Semiconductor Material Grades

Material Grades used in Semiconductor Manufacturing What are the Semiconductor Material Grades? Performance requirements vary based on elastomer location in the process. The advantages of using our elastomer materials include decreased cost of ownership, extended tool Preventative Maintenance (PM) cycles, lower process defects, decreased particle origination and maximised device performance. Below is the table with our recommended material grades (Other […]

Read MoreTypes of Silicone

Types of Silicone: MQ, VMQ, PMQ & FVMQ – what does it all mean? Silicone is used in a wide selection of industries, including Food & Drink, Pharmaceutical to Aerospace. It presents low toxicity, excellent flexibility, resistance to oxygen, UV, ozone and microbial growth. Silicone as a sealing material has one of the greatest scopes of working temperatures. A Standard […]

Read MoreWhat is the difference between Teflon and PTFE?

Teflon™ vs PTFE The sealing industry is full of trade names, technical phrases, and acronyms, which makes it hard to know what is what. In this learning journal, we will explain what Teflon™ and PTFE are, and also the differences. PTFE – what is it? PTFE is a carbon and fluorine synthetic polymer – Polytetrafluoroethylene. It is obtained from Tetrafluoroethylene […]

Read MoreRubber Compound – what is it?

What is a Rubber Compound? There is a misunderstanding that an elastomer compound is made out of one ingredient and that it is the same for every different type of polymer. The fact is that a rubber compound can be a combination of 3 to 15 various elements and thousands of different formations. Standard elastomer composition based on parts per […]

Read MoreOutgassing

How to overcome the consequences of Outgassing Outgassing is defined as “the release of a gas that was dissolved, trapped, frozen, absorbed or adsorbed in some materials’’. Parts of rubber formulation, decomposition products of the ingredients or other gasses trapped in the polymer composition during the moulding process can turn unstable and be released under vacuum conditions. Visual Indications and […]

Read MoreShore A Hardness

What is a Shore A Hardness and why is it important? What is a Shore durometer? The Shore durometer is an instrument used for measuring the material’s hardness, generally rubbers, elastomers, and polymers. The Shore A hardness measurement is called ‘’durometer’’. Tests are carried out on cured rubber according to ASTM D2240, and on a complete O Ring according to […]

Read MoreTemperature range of Viton™

Viton™ (FKM/FPM) temperature range Fluoroelastomers are known for their excellent resistance to chemicals and temperatures. They have low compression set, resistance to ozone, very low gas permeability, are self-extinguishing and have remarkable ageing features. Viton™ has developed a significant eminence in the sealing industry due to its performance features. Fluoroelastomers are highly fluorinated carbon-based rubbers that are used in installations […]

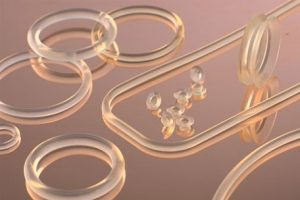

Read MoreWhy should you use Food-Grade Silicone?

Silicone compliant with Food Regulations, what are the features? There are plenty of options when it comes to sealing materials. However, in the food processing industry, it is very important that each element that interacts with the seal is left untouched. Furthermore, despite the fact that silicone is ‘practically’ non-toxic, only a particularly developed food grade silicone is suitable for […]

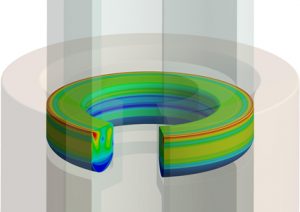

Read MoreFinite Element Analysis (FEA)

Anticipative behavioural techniques to imitate real-life settings Finite Element Analysis (FEA) is a computer-based manipulation. It is used to examine engineering applications and sealing elements to perceive their behaviour under several circumstances. This analysis, therefore, entails Finite Element Modelling (FEM). FEM is frequently used for new element design, or to improve an existing product design. Furthermore, virtual medium allows engineers to […]

Read MoreFDA Rubber Materials

Selecting The Best FDA Rubber Material The following article provides an overview of all M Barnwell Services popular FDA Rubber Compounds, which are also compliant with EC1935/2004 & EC2023/2006 Regulations. Fluorocarbon (Viton®/FKM) For high-temperature and chemical resistance. It’s transparent underwater but does not absorb it. Working temperature scope is measured to be between -20°C and +205°C (intermittent/compound-specific between -45°C and […]

Read More