Thermal Process

Semiconductor Manufacturing – Thermal Process The term ‘thermal process’ covers a broad scope of installations. These installation temperatures are usually higher than Plasma Processes and can go up to +300°C. In addition, thermal-based installations require not only sealing materials with a particular chemical resistance demands but also ones with good mechanical features and low compression set. Thermal Processes include: Atomic […]

Read MoreWet Chemical Process

Semiconductor Manufacturing – Wet Chemical Process Electro or Electroless Chemical Deposition Despite the fact that this is a smaller division of the semiconductor chip manufacturing industry, it still plays a crucial role. Wet chemical processes are used in etching, cleaning, and other stages in chip manufacturing. Wafers can be cleaned and rinsed after the first wafer preparation. In this stage, […]

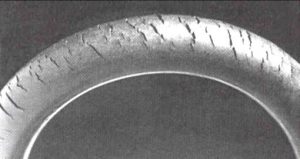

Read MoreOzone damage of O Rings

Ozone Rubber Deterioration O Rings are amongst the most commonly used seals. They come in a wide selection of tough materials, serving a wide range of industries including Pharmaceutical, Food & Beverage, Chemical Processing, Petrochemical and many more. They provide a high-quality seal and reliability for many different fields and are adequate for the most exigent applications. Due to O […]

Read MoreSemiconductor Manufacturing Process

Semiconductor Manufacturing Process Overview: Plasma, Thermal & Wet Processes Synergistic process technologies that have some of the most demanding environments for elastomer materials are etch, ash/strip, deposition, thermal and plasma processing. They are frequently confronted throughout the manufacture of: MEMS Flat Panel Displays (FPD) LED/OLED HBLED Solar Cells (Concentrator, Multi-Crystalline, Crystalline) Logic and memory Photovoltaic cells Optoelectronics Power devices Semiconductor […]

Read MorePlasma Process

Semiconductor Manufacturing – Plasma Process The plasma process is one of the most hostile for elastomers, especially those vulnerable to chemicals and/or close to the substrate or the wafer. The most hostile plasma processes for elastomers include oxygen resist strip and radical based plasmas (such as remote NF3) and chamber cleans using remote plasma sources (RPS). Every seal, especially one […]

Read MoreSemiconductor Material Grades

Material Grades used in Semiconductor Manufacturing What are the Semiconductor Material Grades? Performance requirements vary based on elastomer location in the process. The advantages of using our elastomer materials include decreased cost of ownership, extended tool Preventative Maintenance (PM) cycles, lower process defects, decreased particle origination and maximised device performance. Below is the table with our recommended material grades (Other […]

Read MoreTypes of Silicone

Types of Silicone: MQ, VMQ, PMQ & FVMQ – what does it all mean? Silicone is used in a wide selection of industries, including Food & Drink, Pharmaceutical to Aerospace. It presents low toxicity, excellent flexibility, resistance to oxygen, UV, ozone and microbial growth. Silicone as a sealing material has one of the greatest scopes of working temperatures. A Standard […]

Read MoreWhat is the difference between Teflon and PTFE?

Teflon™ vs PTFE The sealing industry is full of trade names, technical phrases, and acronyms, which makes it hard to know what is what. In this learning journal, we will explain what Teflon™ and PTFE are, and also the differences. PTFE – what is it? PTFE is a carbon and fluorine synthetic polymer – Polytetrafluoroethylene. It is obtained from Tetrafluoroethylene […]

Read MoreRubber Compound – what is it?

What is a Rubber Compound? There is a misunderstanding that an elastomer compound is made out of one ingredient and that it is the same for every different type of polymer. The fact is that a rubber compound can be a combination of 3 to 15 various elements and thousands of different formations. Standard elastomer composition based on parts per […]

Read MoreOutgassing

How to overcome the consequences of Outgassing Outgassing is defined as “the release of a gas that was dissolved, trapped, frozen, absorbed or adsorbed in some materials’’. Parts of rubber formulation, decomposition products of the ingredients or other gasses trapped in the polymer composition during the moulding process can turn unstable and be released under vacuum conditions. Visual Indications and […]

Read More