Compression Set

What is a compression set? In a nutshell, the compression set of a material is the permanent deformation remaining after the removal of a force that was applied to it. ‘Set’ is a term that is used to characterise something that had been deformed by a force and when released does not fully return to its original shape, it has […]

Read MoreElastomers for Food Water and Dairy

Food-grade Rubbers for Hygienic Industries M Barnwell Services understand the specific and very demanding requirements sealing materials must meet in Food, Dairy, and Water industries. Over the last 50 years, we have gained knowledge and expertise in chemically resistant food grade elastomer seals for use with hostile media observed in Clean-in-Place (CIP) and Steam-in-Place (SIP) routines and high-temperature steam sterilisation. […]

Read MoreViton™ O Rings vs Nitrile O Rings

Comparison of two of the most commonly used elastomers – Viton™ O Rings vs Nitrile O Rings As two of the most widely used elastomers, Viton™ (FKM/FPM) and Nitrile (NBR) have some great properties. Both provide a supreme compression set and have an extensive range of purposes in both domestic and industrial installations. Nevertheless, they’re not totally equal in their […]

Read MorePS-SEAL® Non-Standard lip materials

Garlock PS-SEAL® Non-Standard lip materials for dynamic applications For a number of years, Garlock’s Fluoroelastomer (FKM/FPM) PS-SEAL® Standard with a GYLON® Black lip is known for its industry-leading reliability when sealing critical applications. However, when the sealing requirement requires an alternative solution to an FKM, Garlock also created the PS-SEAL® Non-Standard. Generally, the Garlock PS-SEAL® Non-Standard seal can be easily […]

Read MoreSealing products for the Semiconductor Industry

Sealing products for the Semiconductor manufacturing industry M Barnwell Services offers an extensive range of Semiconductor Seals that can operate in deposition, etch, ash/strip, plasma, wet chemical and thermal processes. These products can be used within the semiconductor and related manufacturing industries: Logic and memory MEMS HBLED Power Devices Solar cells (crystalline, multi-crystalline, concentrator) Flat-panel display Optoelectronics LED/ OLED We […]

Read MoreThermal Process

Semiconductor Manufacturing – Thermal Process The term ‘thermal process’ covers a broad scope of installations. These installation temperatures are usually higher than Plasma Processes and can go up to +300°C. In addition, thermal-based installations require not only sealing materials with a particular chemical resistance demands but also ones with good mechanical features and low compression set. Thermal Processes include: Atomic […]

Read MoreWet Chemical Process

Semiconductor Manufacturing – Wet Chemical Process Electro or Electroless Chemical Deposition Despite the fact that this is a smaller division of the semiconductor chip manufacturing industry, it still plays a crucial role. Wet chemical processes are used in etching, cleaning, and other stages in chip manufacturing. Wafers can be cleaned and rinsed after the first wafer preparation. In this stage, […]

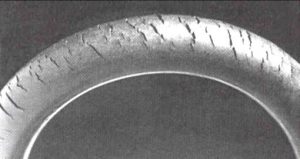

Read MoreOzone damage of O Rings

Ozone Rubber Deterioration O Rings are amongst the most commonly used seals. They come in a wide selection of tough materials, serving a wide range of industries including Pharmaceutical, Food & Beverage, Chemical Processing, Petrochemical and many more. They provide a high-quality seal and reliability for many different fields and are adequate for the most exigent applications. Due to O […]

Read MoreSemiconductor Manufacturing Process

Semiconductor Manufacturing Process Overview: Plasma, Thermal & Wet Processes Synergistic process technologies that have some of the most demanding environments for elastomer materials are etch, ash/strip, deposition, thermal and plasma processing. They are frequently confronted throughout the manufacture of: MEMS Flat Panel Displays (FPD) LED/OLED HBLED Solar Cells (Concentrator, Multi-Crystalline, Crystalline) Logic and memory Photovoltaic cells Optoelectronics Power devices Semiconductor […]

Read MorePlasma Process

Semiconductor Manufacturing – Plasma Process The plasma process is one of the most hostile for elastomers, especially those vulnerable to chemicals and/or close to the substrate or the wafer. The most hostile plasma processes for elastomers include oxygen resist strip and radical based plasmas (such as remote NF3) and chamber cleans using remote plasma sources (RPS). Every seal, especially one […]

Read More