Semiconductor Manufacturing Seals

Semiconductor Manufacturing Seals: Ensuring Purity, Sealing Perfection in Semiconductor Processes

M Barnwell Services specialises in tailored semiconductor manufacturing seals, addressing challenges in purity, process safety, and integrity. Our products cater to various systems, ensuring product quality, personnel safety, and operational efficiency.

Key Semiconductor Manufacturing Seals Applications:

- Process Systems: Ultrapure Water, Central Vacuum, Chemical Distribution.

- Utility Systems: Central Steam, Cooling Water, Wastewater.

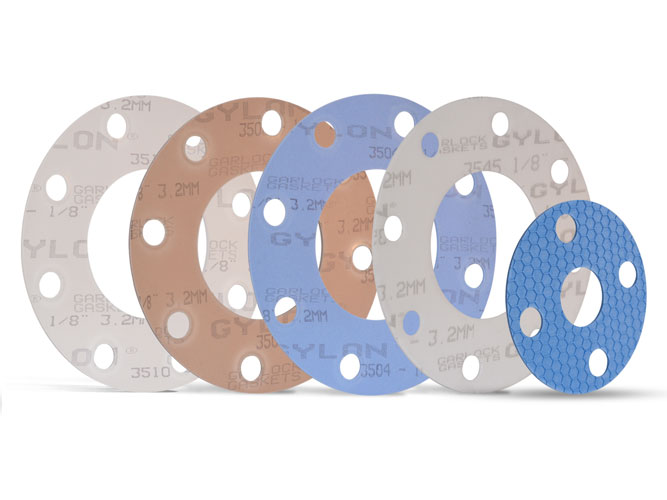

GYLON® High-Performance PTFE Material:

Manufactured using a proprietary process, GYLON® minimises creep and cold flow. This provides superior leak prevention for increased uptime and cost savings.

Semiconductor Process Systems:

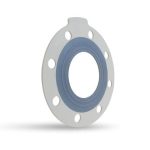

Ultrapure Water Systems / STRESS SAVER® 3522 & STRESS SAVER® 370:

Reduce cross-contamination risks with molded-in stress concentrators for reliable sealing in imperfect flange connections.

For microelectronics manufacturers, ensuring long-term reliability and system efficiency is crucial. Garlock’s STRESS SAVER® 3522 and STRESS SAVER® 370 are designed specifically for ultrapure water systems. They effectively reduce cross-contamination risks associated with traditional flange gaskets. Featuring molded-in stress concentrators, these gaskets allow for low-load and reliable sealing, even in less-than-perfect flange connections. Special high-purity packaging and handling options are available upon request. This tailored solution addresses contamination concerns and promotes optimal performance in ultrapure water systems.

Features and Benefits of STRESS SAVER® 3522:

Critical to semiconductor manufacturing are Ultra Pure Water (UPW) and acid handling/neutralisation. Pipework, whether stainless steel or non-metallic like PVDF, demands seals meeting high purity standards, chemical compatibility, and effective sealing at low bolt load.

The STRESS SAVER® 3522 excels, offering safety, performance, and cost benefits. Molded raised ribs enhance the seal by concentrating compressive load. With superior resilience and physical properties compared to virgin PTFE and ePTFE, it ensures reliability.

Composed of 100% PTFE, STRESS SAVER® 3522 is compatible with chemicals and byproducts. It boasts excellent chemical resistance, high resilience, and prevention of cold flow. Versatile, it suits metallic and non-metallic piping with flat or raised face flanges, making it ideal for non-metallic pipework materials like PVC, FRP, PVDF, CPVC, and PP.

The homogenous construction, a single-piece design, avoids permeation, delamination, or fold-over, ensuring reliability. Operating between -268°C to +260°C, it provides a robust solution across a wide temperature range.

Chemical Dosing / GYLON® Gaskets:

Limit creep and cold flow for leak containment and hazard prevention in semiconductor fabrication.

In semiconductor fabrication, where chemistries are aggressive and volatile, we design piping systems prioritising human safety and environmental compliance. Our proprietary gaskets ensure leak containment, prevent hazards, and offer reliable, chemically compatible sealing by limiting creep and cold flow over time.

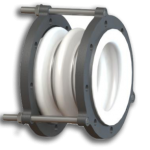

Chemical Handling & Distribution Systems / GYLON® Gaskets & SURE-LINK™ Pipe Expansion Joints:

Ensure leak-free, chemically compatible sealing in bulk chemical distribution piping.

For the safe transportation of critical process media in semiconductor fabrication piping systems, we utilise advanced gasket and expansion joint technologies. Our industry-proven GYLON® gasket solutions resist creep and cold flow, ensuring long-term, reliable sealing for process efficiencies and minimising unexpected system downtime. SURE-LINK™ PTFE Expansion Joints are designed for high-pressure, overhead installations, offering full vacuum capabilities.

Chemical Exhaust Tool Hook-Up / GYLON® Style 3545 Gasket:

Achieve leak-free integrity in chemical exhaust systems with the GYLON® 3545.

Processes like etching, coating, cleaning, and vaporisation in semiconductor fabrication produce chemical-laden vapors that must be evacuated without contamination. Garlock’s GYLON® 3545, with a conformable microcellular PTFE body and rigid center layer, ensures leak-free integrity, offering up to 70% compressibility, universal chemical compatibility, and a tight, reliable seal in chemical exhaust systems.

Features and Benefits of GYLON® Style 3545 Gasket:

In semiconductor processing, various chemicals are utilised, and their vapors are extracted through the exhaust tool hook-up to scrubbing and recovery systems. Gaskets in the exhaust tool hook-up play a crucial role, requiring both chemical resistance and physical resilience to avoid potential issues.

The GYLON® 3545 stands out among gasket materials for exhaust tool hook-ups, offering safety, performance, and cost benefits. This high-performance gasket is crafted from multi-layered PTFE, ensuring permanent resilience. Its central core features a hard PTFE pressure-resistant layer surrounded by soft, compressible micro-cellular PTFE outer layers, providing superior resilience and physical properties compared to virgin PTFE and ePTFE.

GYLON® 3545, being 100% PTFE, is fully compatible with various chemicals and byproducts used in semiconductor processes, including hydrofluoric acid, hydrochloric acid, nitric acid, sulfuric acid, ammonia, ammonium salts, and calcium salts. It excels in chemical resistance, high resilience, preventing cold flow, and is suitable for pressure and vacuum duties.

Operating in a wide temperature range from -268°C to +260°C, GYLON® 3545 handles demanding conditions. With a minimum load of 17 N/mm2 and a maximum load of 140 N/mm2, it ensures reliable performance across a spectrum of semiconductor applications.

Semiconductor Utility Systems:

Hydronics – Central Hot and Cold Water / MULTI-SWELL® Style 3760 Gaskets:

React with targeted media for controlled swell technology, providing tight seals and forgiveness in irregular flange conditions.

MULTI-SWELL® Style 3760 and 3760-U are crafted from synthetic fibers and proprietary fillers, securing tight seals in central hot and cold-water systems. Approved for potable water systems, these gaskets support water conservation with controlled swell technology, combating relaxation in flange assemblies, and providing sealing integrity over time. They are twice as compressible as standard fiber gaskets, forgiving in irregular flange conditions, and making installation easier.

Central Thermal and Waste Systems / Style P2000 Expansion Joint:

Combine optimal mechanical design with advanced technology for sustainability in central thermal and waste systems.

For sustainability in central thermal and waste systems, the Style P2000 expansion joint combines optimal mechanical design with advanced textiles and elastomer technology. With exceptional pressure and movement capability, it addresses common piping applications, meeting critical safety and sustainability requirements.

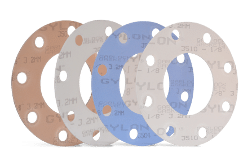

Utility Maintenance / GYLON EPIX® Style 3500, 3504, 3510 Gaskets & Style P2000 Expansion Joints:

Prevent service interruptions with GYLON EPIX® flange gaskets and ensure long-term reliability with the Style P2000 in various system applications.

To prevent service interruptions in utility maintenance, the GYLON EPIX® family of flange gaskets is designed for bolt-load-challenged connections, simplifying system maintenance. The Style P2000 offers long-term reliability in various flange connections and system applications, offsetting strains from thermal expansion and contraction and accommodating significant pressure and vacuum system upsets. Available in various materials, it provides exceptional pressure and movement capabilities for safety-conscious pump and piping applications.

Other Semiconductor Manufacturing Seals:

- O Rings

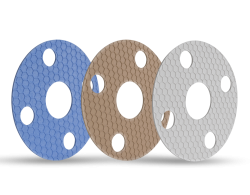

- Gaskets

- Lip Seals

- Diaphragms

- V Rings

- Piston Seals

- Cassette Seals

- Custom Moulded Seals

- Metal Seals

- Quad Rings

These seals play crucial roles in maintaining the integrity of semiconductor processes, ensuring the protection of sensitive components from contamination, and facilitating optimal performance of semiconductor equipment. The choice of seal type depends on the specific requirements and conditions of the semiconductor manufacturing application

As well as Semiconductor Manufacturing Seals, M Barnwell Services also provides a range of PTFE products for all industries. These include PTFE Gaskets, PTFE O Rings, and PTFE Diaphragms.

Visit the Semiconductor industry page for more information on our specialist solutions for the Semiconductor industry.

For information on other materials we offer visit our Material Properties page.

E&OE. Information gathered from manufacturing partners.