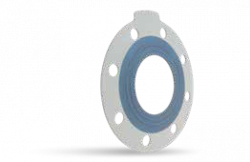

STRESS SAVER® Gaskets

Superior low-torque gaskets for metallic or non-metallic flanges

M Barnwell Services is one of the UK’s largest independent stockists and distributors of STRESS SAVER® Gaskets. Depending on the application M Barnwell Services and it’s manufacturing partners offer full batch traceability throughout the manufacturing process and provide certification when available.

STRESS SAVER® GYLON® 3504

Helps to seal low-load flanges. The moulded raised ribs help to create a tighter seal by concentrating the compressive load, ideal for lightweight piping applications. Out patented STRESS SAVER® GYLON® 3504 combines these proven sealing advantages with the performance characteristics of the industry-recognised GYLON® 3504. The combination of these two time-tested configurations makes it the ideal sealing solution.

Features and Benefits

- Chemical Resistance – perfect for a broad scope of caustics and acids, helping to simplify the selection process

- Outstanding Physical Characteristics – more superior temperature and pressure capabilities than rubber gaskets

- Versatility – suitable for both metallic and non-metallic piping with either flat or raised face flanges (sizes 1/2″ through 12″, for 150# and 300# classes as well as ASME and DIN standards)

- High-Purity – compliant with FDA, USP Class VI, and able to meet the strict demands of NSF 61 for potable (drinking) water

- Limited Creep and Cold-Flow – vastly lessen the leakage post-installation and system cycling

- Uniform Construction – single-piece design helps avoid delamination, permeation, fold-over of PTFE envelopes, or splitting when installed against raised sealing surfaces

STRESS SAVER® XP

Single-piece moulded design manufactured from high performance, proprietary blend of Fluoroelastomers (FKM/FPM). Ideal for use with steam, potable (drinking water), and harsh chemicals.

Features and Benefits

- Chemical Resistance – high-performance Fluoroelastomer (FKM/FPM), outperforms conventional Fluoroelastomers in steam and harsh chemical applications, along with enhanced heat resistance

- Tighter Seal – ideal for flat-faced non-metallic flanges, lower seating stress than expanded PTFE gasket

- Compliant with NSF 61 for potable (drinking) water

- Suitable for use in CORZAN® (CPVC) Piping thanks to its Lubrizol FBC™ System Compatibility

Corzan is a registered trademark of Lubrizol®

STRESS SAVER® 370

White Ethylene Propylene (EPDM) rubber moulded with a pure PTFE envelope. Proprietary method bonds the PTFE to the EPDM elastomer without the use of adhesives, eliminating envelope fold-over concerns during installation.

Features and Benefits

- Chemical Resistance – pure PTFE sealing surface withstands several moderate chemicals

- Fabricated of FDA compliant ingredients

- Tighter Seal – ideal for flat-faced non-metallic flanges, lower seating stress than expanded PTFE gasket

- High-Purity, impurity-free white Ethylene Propylene (EPDM) makes it perfect for ultrapure applications such as Food and Pharmaceutical industries

The STRESS SAVER® Family of Products

- Industries served – Chemical Processing, Semiconductor, Food, Pharmaceutical, Pulp & Paper, Potable (drinking) Water

- Ideal for – PVC, FRP, PVDF, CPVC, Polypropylene, Cast and Ductile Iron

- Flat Face Flange – STRESS SAVER® GYLON® 3504, STRESS SAVER® XP, STRESS SAVER® 370

- Raised Face Flange – STRESS SAVER® GYLON® 3504

Typical Physical Characteristics

| STRESS SAVER® GYLON® 3504 | STRESS SAVER® XP | STRESS SAVER® 370 | |

|---|---|---|---|

| Composition | PTFE with aluminosilicate microspheres | Proprietary blend of Fluoroelastomer (FKM/FPM) ShA 70 | 100% virgin PTFE bonded to 65 ShA Ethylene Propylene (EPDM) |

| Colour | Blue | Black | PTFE: sky blue EPDM: off-white |

| Size Range | 1/2" (12.7mm) - 12" (304.8mm) | 1/2" (12.7mm) - 24" (609.6mm) | 1/2" (12.7mm) - 24" (609.6mm) |

| Temperature | |||

| Minimum | -450°F (-268°C) | -15°F (-26°C) | -40°F (-40°C) |

| Ideal Operating Limit | +400°F (+204°C) | +250°C (+121°C) | +200°F (+93°C) |

| Maximum | +500°F (+260°C) | +400°F (+204°C) | +300°F (+149°C) |

| Pressure | |||

| Ideal Operating Limit | 750 psig (52 bar) | 150 psig (10 bar) | 150 psig (10 bar) |

| Maximum | 800 psig (55.2 bar) | 250 psig (17 bar) | 250 psig (17 bar) |

| Media | All solvents, moderate caustics and acids, hydrocarbons, refrigerants, cryogenics and potable (drinking) water | Potable (drinking) water, stream, most hydrocarbons, gases, solvents | Moderate acids, caustics, gases, water, hydrocarbons |

| M&Y | 2.0 / 400 psi | 0.5 / 100 psi | 2.0 / 400 psi |

This is a general guide and should not be the sole means of selecting or rejecting this material.

M Barnwell Services is proud to be Garlock’s UK Strategic Partner, stocking and supplying their sealing portfolio. The range of Garlock seals delivers solutions that improve plant productivity, reduce costs, and comply with increasingly stringent environmental regulations.

If you would like more information about our range of Agitator and Mixer Seals contact a member of the team. E & OE.