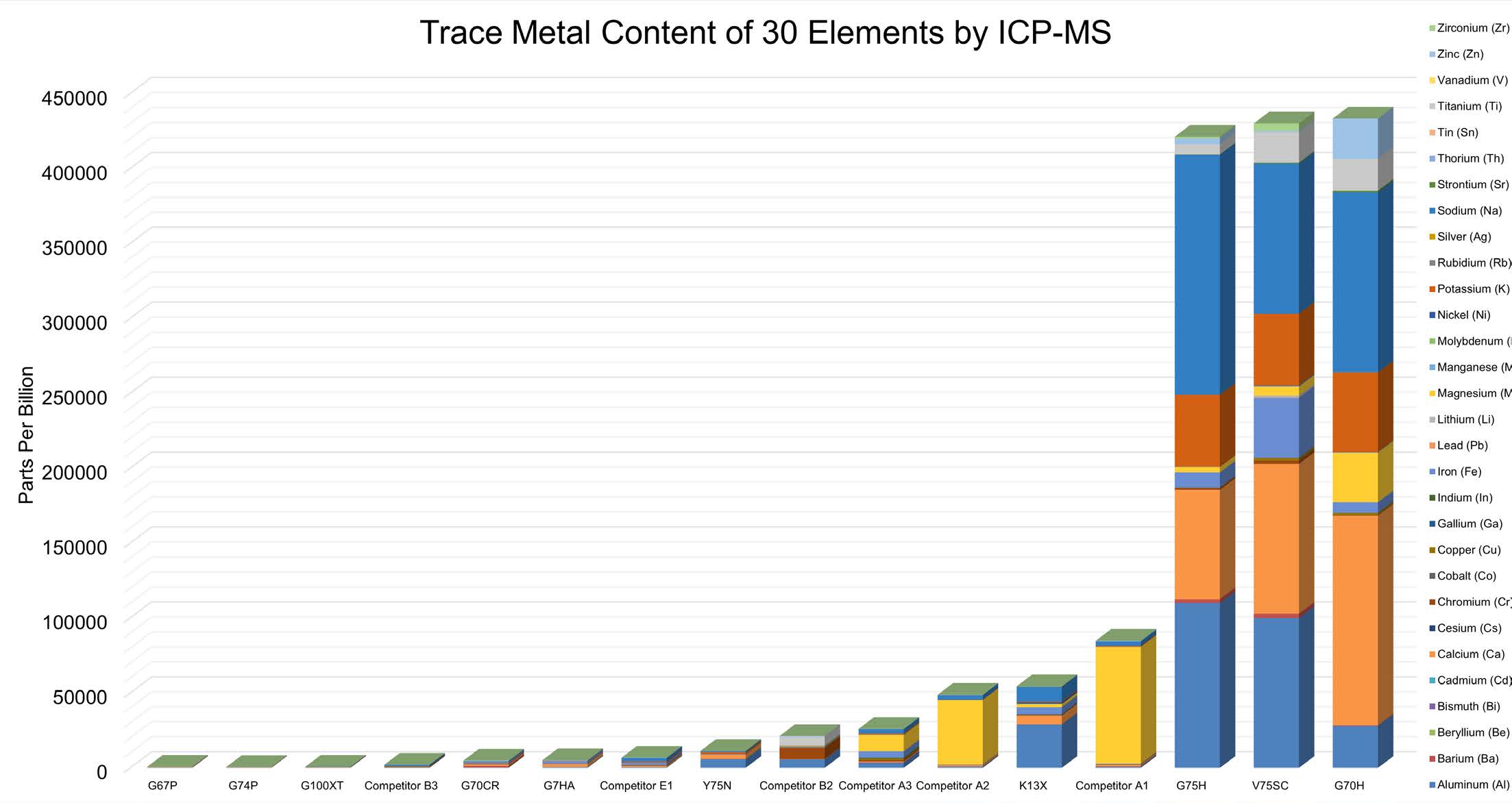

How Clean are Your Seals ?

Trace, Test and The Importance of Cleaning Your Seals During routine operation equipment will naturally wear. The components that are most at risk as those exposed to harsh chemicals or physical environments. Seals are no exception as they will slowly degrade over time. While this may not dictate the maintenance cycle of the tool itself, they will release by-products and […]

Read MoreThe Benefits of Custom Seals

Custom Seals – The ultimate guide & CNC Machining When choosing the correct sealing solution for the application/industry, custom seals offer a range of fantastic benefits. Whilst standard seals serve a purpose for common applications, custom seals should be considered when precision, reliability, longevity and optimal performance in challenging environments are crucial to their operations and overall success. If you […]

Read MoreM Barnwell Services Introduces Seal Maker 500e

In the world of industrial engineering, precision is everything. That’s why we’re excited to announce the latest addition to our arsenal: the Seal Maker 500e. This cutting-edge CNC system takes precision to new heights, allowing us to craft seals up to 520mm with unmatched accuracy. With three onsite machines now at our HQ in Smethwick, we can offer even faster […]

Read MoreHow Are O Rings Manufactured?

M Barnwell Services explains How Are O Rings Manufactured? Please find below our step-by-step guide on how O Rings are manufactured. STEP 1: O Rings Moulding The first step in the O Ring manufacturing process is selecting the correct tools for moulding. The correct tools are dependent on the size of the O Ring that is being manufactured. Smaller […]

Read MoreBenefits of Kitting, Assembly and Sub-Assembly

What benefits can Kitting, Assembly & Sub-Assembly bring to your business? The manufacturing processes of Kitting, Assembly & Sub-Assembly are quite similar and very beneficial to successful supply chain management solutions. We provide this service due to our buying power and a thorough understanding of our customers’ needs. With over 50 years of experience in fluid sealing, our team of […]

Read MoreWhat is Pigging?

What is Pigging and how does it work? What is Pigging – An Overview M Barnwell Services offer a comprehensive range of replacement Pipeline Pigging System Seals available in many different sizes and materials. If you would like further information about our range of products and/or services, or contact a member of the team.

Read MoreISIR Seals

ISIR Seals & Gaskets: (Initial Sample Inspection Report) M Barnwell Services provide ISIR Seals (Initial Sample Inspection Report), which is a vital step in the sampling process that documents the dimension and material results of the first product batch, known as the ‘initial sample’. Before going into series production, these products are produced via series production processes under realistic conditions. […]

Read MorePPAP Level 3

PPAP Level 3 – PSW with product samples and complete supporting data What is it PPAP Level 3? PPAP Level 3 (Production Part Approval Process) is the 3rd level of the automotive industry standard that ensures engineering design and product specification requirements are met. Read more about the first two PPAP levels here. It may be included during: Design Documentation […]

Read MorePPAP Level 2

PPAP Level 2 – PSW (Part Submission Warrant) with product samples and limited supporting data What is it? M Barnwell Services provides PPAP Level 2 (Production Part Approval Process), which is the automotive industry standard that ensures product specification and engineering design requirements are met. For a general overview of PPAP visits the What is PPAP page. The process may […]

Read MorePPAP

What is PPAP? M Barnwell Services provide ISIR (Initial Sample Inspection Report) and PPAP on selected items which consists of 5 levels, most commonly being 2/3. PPAP (Production Part Approval Process) is the automotive industry standard that ensures production specification and engineering design requirements are met. Providing PPAP documentation ensures that suppliers and customers have a precise understanding of the […]

Read More