NORSOK M-710

NORSOK M-710 – Qualification of non-metallic sealing materials and manufactures NORSOK M-710 (Norsk Sokkels Konkuranseposisjon) are standards developed by the Norwegian Technology Centre. What is NORSOK M-710? NORSOK M-710 is a globally accepted standard implemented by the Norwegian Petroleum Industry. It defines the qualification demands of polymer (non-metallic) sealing materials and manufactures. It has started with mostly European and Norwegian […]

Read MoreSelecting Pipe Flange Gaskets

Selecting Pipe Flange Gaskets – tips and common standards M Barnwell Services supplies and distributes pipe flange gaskets in a broad range of sizes and materials. Custom made bespoke gaskets can also be produced. Pipe Flange Gasket Types The most commonly used gaskets in pipes are standard flange gaskets in either fibre, spiral wound or rubber. Furthermore, for very large […]

Read MorePurity of Pharmaceutical Seals

The purity of Pharmaceutical Seals: High-Performance Sealing Solutions The Pharmaceutical field comprises of manufacture, extraction, processing, purification, and packaging of medical substances that are intended for use as medication for humans and animals, therefore purity of pharmaceutical seals is critically important. Pharmaceutical production is segregated into two principal phases. The first phase, manufacture or primary processing is the manufacture of […]

Read MoreUpstream Gas & Oil Sealing Considerations

Upstream Gas & Oil Sealing Considerations (extraction and production) Upstream Gas & Oil The upstream section of the Gas & Oil industrial method is preoccupied with extraction and production of natural gas and raw oil. Installations in the upstream section are frequently placed in hard to reach spaces, from the Arctic to deep sea drilling platforms. Processing expenses are also […]

Read MoreFood Safe Silicone

Is Silicone Food Safe? When producing high-performance O Rings and bespoke sealing solutions for the food process industries, protection has to be the priority. M Barnwell Services provide products manufactured from a broad selection of rubber materials and include Silicone. However, how prudent is silicone sealing, and how is consumers’ health protected? At M Barnwell Services our sealing proficiency incorporates not […]

Read MoreCommon Gas & Oil Seal Failure Causes

Why is Gas & Oil Seal Failure Quite Common? Only a number of engineering elements are expected to operate under more difficult conditions than those of Gas & Oil Installations. The environments included in Gas & Oil production consist of severe stresses, temperatures, and chemical media. Additionally, they place rigid requirements on equipment, which must be accurately designed to guarantee […]

Read MoreISO 10423 (API 6A)

ISO 10423 (API 6A) – International Standard for Petroleum and Natural Gas Industries ISO (the International Organization for Standardization) is a global federation of national standard bodies. International Standards are set by ISO technical committees that concentrate on and express a specific area of profession. API (American Petroleum Institute) is a trade association that presents all angles of America’s oil […]

Read MoreHow important is FEA Simulation in Gas & Oil

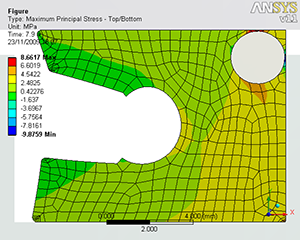

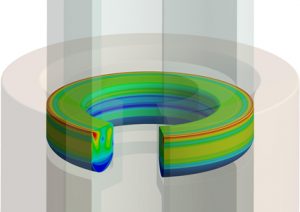

FEA Simulation in Gas & Oil What is FEA Simulation Finite Element Analysis (FEA) is a computer-based manipulation that evaluates how elastomer components are prone to function in real-life installations. This innovative method can ascertain how exposure to extreme temperatures and pressures and aggressive chemical circumstances can influence the components. Adequate use of FEA Simulation can eliminate the necessity for […]

Read MoreElastomer Testing & Analysis

Elastomer Testing & Analysis Prior To Assembly / After Failure M Barnwell Services uses a specialist selection of independent Testing & Analysis consulting services when inspecting polymeric materials. Some key Elastomer Testing abilities include: Failure analysis Thermo-mechanical assessment Chemical compatibility Microscopy Explosive Decompression / Rapid Gas Decompression (RGD) The development consists of a broad scope of machinery committed to the […]

Read MoreFinite Element Analysis (FEA)

Anticipative behavioural techniques to imitate real-life settings Finite Element Analysis (FEA) is a computer-based manipulation. It is used to examine engineering applications and sealing elements to perceive their behaviour under several circumstances. This analysis, therefore, entails Finite Element Modelling (FEM). FEM is frequently used for new element design, or to improve an existing product design. Furthermore, virtual medium allows engineers to […]

Read More