How To Fit A Shaft Repair Sleeve

How to remove and install a Shaft Repair Sleeve This is an instructional guide on the process of how to remove and install a Shaft Repair Sleeve / Redi-Sleeve / Shaft Wear Sleeve. If you are unsure always read the instructions or contact a member of the team today. Fitting Clean the surface where the seal has worn the shaft. […]

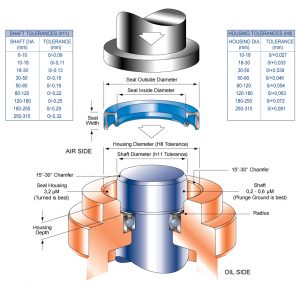

Read MoreWhat are Oil Seals?

What are Oil Seals – A guide to Oil and Rotary Shaft Seals Also known as a Rotary Shaft Seal, Shaft Seal, Lip Seal, Elastomeric Lip Seal or any variation of these. It is a simple device for excluding dust, dirt, water or any other contaminant whilst retaining lubricant in rotary shaft equipment. Generally, it has been developed as a […]

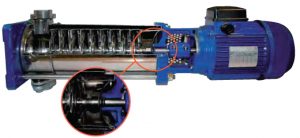

Read MoreA Mechanical Seal Guide

The Mechanical Seal – one of the most effective ways of sealing rotating shafts. This consists of two plane faces arranged perpendicular to the axis of the rotating shaft (which gives rise to the alternative name “radial face seal”). One face is fixed to the equipment casing or vessel, while the other is fixed to the shaft and so rotates […]

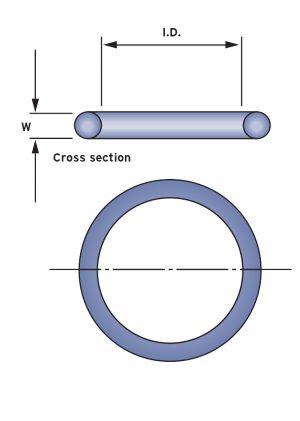

Read MoreWhat is an O Ring

What is an O Ring – Selecting, Material and Storage In this news/blog item, we look to answer what is an O Ring? The O Ring or Toroidal Seal is a simple, versatile and economical device with a vast range of uses. The most common of these is a static seal replacing a gasket or sealing washer, but it can […]

Read MoreO Ring Lube – why and when to use

In many applications, there is a need to minimize the frictional forces created by a seal. The simplest way to reduce this is to use an O Ring Lubricant. M Barnwell Services provides a barium base petroleum grease O Ring Lube agent fit for that purpose. Our O Ring Lube (available in various sizes) can be applied to the surface […]

Read MoreO Ring Material Selection – Overview

Our most popular O Ring Material is Nitrile (NBR) 70° Shore ‘A’. This is an Elastomer seal that can do the majority of standard industrial applications. These include Oil, Petrochemical, Water and the majority of chemicals up to 100°C and 1500psi (providing the mating surfaces and housings are adequate). For low temperatures (below -30°C), high temperatures and pressures, as well […]

Read MoreAnother Sealing First For M Barnwell Services

In January 2016, M Barnwell Services Sales Co-ordinator Steve Gibson received an order to produce their largest ever Chevron Seal. The hydraulic seal weighed in at 15 kilos and had size dimensions of 1270mm x 1320mm x 200mm. The rubberised fabric split seal will be used in an injection moulding machine. Steve Gibson said: “I have been in the industry […]

Read MoreLarge O Rings Matters For M Barnwell Services Customers

In October 2015 M Barnwell Services, the UK’s largest stockist and distributor of fluid sealing products, produced its first ever O Ring that was over 10 metres long. Weighing in at 22 Kilos, the 12.5 metre long Nitrile large O Rings is designed to be used in an Electrical Transformer for the Kuwait National Grid. Peter McGarry, Export Manager commented: […]

Read MoreFormula 1 Cars To Contain Barnwell Seals

M Barnwell Services, the UK’s number one distributor and stockist of fluid seal products, has announced a third party partnership that will see Barnwell seals feature in most Formula 1 cars in the 2015 / 16 season. Barnwell’s has already secured long term contracts with other motorsport companies, but the Formula 1 partnership will see the supply of High Performance […]

Read More