What are Static and Dynamic O Rings?

Knowledge Centre – A Guide To Understand O Ring Fundamentals

O Ring applications are divided based on how the surfaces interact: static applications involve sealing between immobile parts, while dynamic sealing occurs when parts move relative to each other. The accompanying illustrations demonstrate Static and Dynamic O Rings sealing scenarios.

Dynamic seals play a vital role in situations where machinery experiences reciprocating, rotating, or oscillating motion against the O Ring. Various environmental factors, including fluid-induced seal swell, surface finish of metal components, lubrication, system pressure, thermal cycling, O Ring compression, elongation, and friction, can significantly affect the performance of dynamic seals. Given the interconnected nature of these factors, it is crucial to consider all of them in dynamic sealing contexts.

M Barnwell Services strongly advises conducting pretests in specific dynamic applications to determine the O Ring‘s lifespan acceptability.

Static Applications

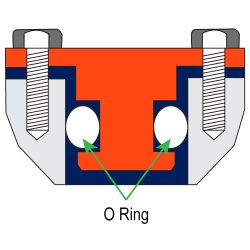

Axial Seals: Pressure is applied to both the top and bottom of the cross-section, commonly seen in flange applications.

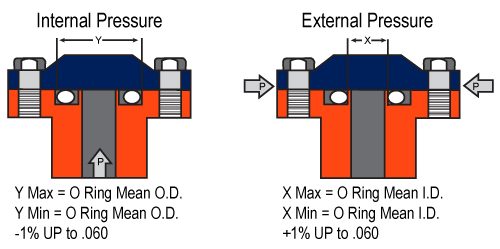

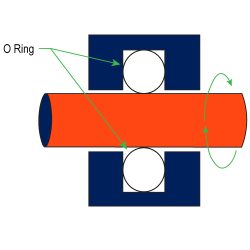

Radial Seals: Compression occurs on both the inner and outer diameters of the O Ring, typical in most end cap applications.

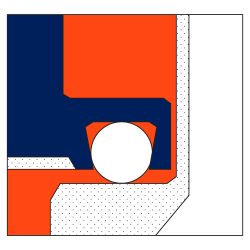

Crush Seals: Compression acts at an angle to the axis of the O Ring due to its confinement within a triangular gland.

Dovetail Gland Seals: Apply pressure to the top and bottom of the O Ring’s cross-section, while a specialised gland configuration securely holds the O Ring in place during operation and/or assembly.

Dynamic Applications

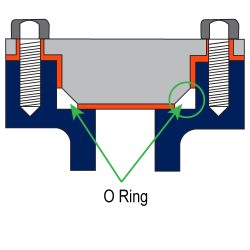

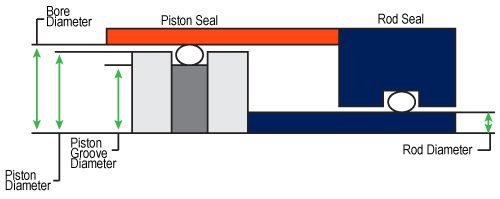

Reciprocating: Movement alternates between backward and forward directions, commonly seen in hydraulic cylinders.

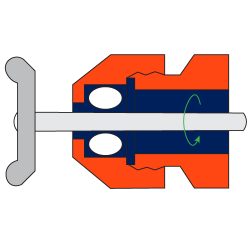

Rotary: Motion involves a shaft rotating in relation to the O Ring, as seen in pumps or motors. Rotation typically happens in a single direction.

Oscillating: Movement involves a shaft rotating backward and forward in a circular arc, with minimal longitudinal motion. An example is a faucet valve stem.

What are the Differences Between Static and Dynamic O Rings?

The choice of O Ring for a specific application hinges on the nature of the surface it interacts with: dynamic, meaning in motion, or static, indicating no movement. When there’s no movement between surfaces, static seals are employed. Conversely, if movement occurs between mating surfaces, dynamic seals are preferred.

Beyond these fundamental differences, other significant distinctions influence seal design. Let’s delve into what sets Static and Dynamic O Rings apart:

1. Materials

Static Seals: In stationary settings, lower durometer materials suffice for low-pressure sealing. Materials with lower abrasion resistance, such as Silicone (VMQ), can accommodate broader temperature ranges.

Dynamic Seals: Continuous motion demands materials with high abrasion resistance and strength. Hydrogenated Nitrile (HNBR), known for its high abrasion resistance, along with low friction compounds like Viton™ FKM Rubbers or self-lubricating materials, are effective choices. Higher durometers are preferable for reducing friction forces.

We also have a wide variety of Extreme Seals, to accommodate every application.

2. Environment of Operation

Static Seals: These seals find application in environments where the mating surfaces they seal experience no continuous movement. Examples include sealing stationary parts or where intermittent movement occurs.

Dynamic Seals: Operate in environments where continuous movement between mating surfaces occurs. Their design specifically accommodates this movement while ensuring that their sealing function remains intact.

3. Durability and Maintenence

Static Seals: Designed for stationary environments, they typically have a longer lifespan when the appropriate material is chosen for chemical and temperature resistance.

Dynamic Seals: Subject to movement and friction, they tend to have a shorter lifespan and need more frequent maintenance to prevent premature failure.

4. Compression

Static Seals: Cross-sections of static seals are generally compressed to a certain degree to ensure effective sealing, typically ranging from 10% to 40%.

Dynamic Seals: Compress their cross-sections for sealing purposes as well, albeit to a lesser degree, typically ranging from 10% to 30%. difference in compression accounts for the dynamic movement and associated friction.

5. Design Complexity

Static Seals: Static seals often have simpler designs since they do not need to accommodate dynamic movement. They may consist of basic shapes like Flat Gaskets or O Rings.

Dynamic Seals: Dynamic seals require more complex designs to withstand continuous movement and associated stresses. They may include features like specialised geometries, multiple sealing elements, or dynamic sealing lip designs.

6. Tolerance to Misalignment

Static Seals: Generally, they’re more forgiving of misalignment between mating surfaces because there’s no continuous movement. They can handle slight deviations in alignment without significantly reducing their effectiveness.

Dynamic Seals: Misalignment can significantly affect dynamic seals due to constant motion. Tight tolerances are typically crucial in dynamic applications to prevent wear, friction, and potential seal failure.

7. Heat Generation

Static Seals: For applications with minimal or intermittent heat generation, static seals may be preferable. The absence of continuous motion results in reduced heat generation during operation.

Dynamic Seals: Continuous movement can result in heat build-up from friction between mating surfaces. Hence, it’s imperative to design dynamic seals to effectively dissipate heat, preventing overheating that could compromise both the seal material and the overall system performance.

8. Pressure Distribution

Static Seals: Pressure distribution across the sealing surface tends to be more uniform since there is no continuous movement to cause variations.

Dynamic Seals: Pressure distribution across the sealing surface may vary due to the dynamic movement and changing contact points between mating surfaces. This can impact seal performance and wear patterns.

Understanding these differences between Static and Dynamic O Rings is essential for selecting the appropriate seal type for specific applications to ensure optimal performance and longevity.

If you would like more information about our range, visit our O Rings webpage, download our catalogue, or contact a member of the team.

E&OE. Information gain from our manufacturing partners.