TB Centre Bonded Mount

TB Centre Bonded Mount – Your Path to Vibration-Free Precision

The TB Centre Bonded Mount is widely utilised for isolating structure-born vibration, shock, and noise. With a straightforward design and cost-effectiveness, these mounts offer reliable solutions for various applications, ensuring enhanced performance and reduced disturbances.

Key Features of the TB Centre Bonded Mount:

- Simple and Fail-Safe Design:

– Features a simple and low-cost fail-safe mount design, ensuring practical and reliable performance.

– Offers a fail-safe mechanism for added security in isolating vibration, shock, and noise. - Rubber Compound Options:

– Supplied with a natural rubber compound as standard, providing effective isolation.

– Available in alternative compounds such as CR (Chloroprene), NBR (Nitrile), or EPDM (Ethylene Propylene Diene Monomer) upon request.

Applications:

- Vehicle Cabs:

Extensively used in vehicle cabs to enhance operator comfort by isolating structure-born vibrations. - Compressors, Engines, and Pumps:

Applied in various machinery components, including compressors, engines, and pumps, to minimize vibration, shock, and noise. - Air Conditioning Units:

Utilised to isolate air conditioning units, ensuring a quieter and more comfortable environment. - Engine Exhaust Mounts (High-Temperature Rubber Compound):

Specifically designed for engine exhaust mounts, it features a high-temperature rubber compound to withstand elevated temperatures.

In summary, the TB Centre Bonded Mount stands as a cost-effective and reliable solution for isolating structure-born vibration, shock, and noise in diverse applications. With their fail-safe design and rubber compound options, these mounts contribute to improved equipment performance and operator comfort.

Technical Data:

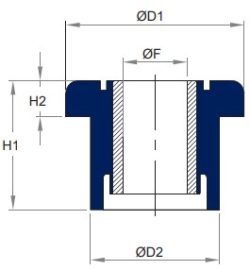

| Part Number | D2 | H1 | F | D1 | H2 | Max. Axial Load (kg) | Deflection (mm) |

|---|---|---|---|---|---|---|---|

| TB2818 | 20.1 | 17.5 | 10 | 27.7 | 5.6 | 56 | 0.64 |

| TB4525 | 31.5 | 25.4 | 13 | 44.5 | 10.4 | 155 | 1.02 |

| TB5133 | 34.3 | 35 | 13 | 50.8 | 13.5 | 211 | 1.52 |

| TB6445 | 41.1 | 44.5 | 16 | 63.5 | 15.7 | 334 | 1.62 |

| TB8423 | 38 | 23 | 16 | 84 | 16 | 334 | 1.62 |

| TB9551 | 56 | 50.8 | 20 | 95 | 25.4 | 395 | 1.70 |

| Part Number | H +/- 0.03mm | Lo | Ko | So | T +/-0.03mm | R +/-0.015mm |

|---|---|---|---|---|---|---|

| TB2818 | 5.3 | 32 | 28-30 | 18.6 | 9 | 1.5 |

| TB4525 | 9.7 | 50 | 38-40 | 28.4 | 9.7 | 1.5 |

| TB5133 | 11.4 | 58 | 50-52 | 31.8 | 15.8 | 1.5 |

| TB6445 | 14.2 | 74 | 56-58 | 38.1 | 19.1 | 1.5 |

| TB8423 | 14.5 | 94 | 55-57 | 35.2 | 3 | 1.5 |

| TB9551 | 23.9 | 108 | 75-78 | 50.8 | 19.1 | 3 |

To find out more about our Anti-Vibration Mounts, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.