Steam Resistant O Rings

Steam Resistant O Rings – Crucial for safety around steam

M Barnwell Services has been a trusted provider of O Rings (including Steam Resistant O Rings) to global industry leaders for more than five decades. Being one of the largest independent stockist and distributors of fluid seals in the UK, our customers can rely on us to deliver precise products for their applications.

Our skilled team aids in all production stages – from material and size decisions to prototyping, testing, and final manufacturing. M Barnwell Services and its manufacturing partners ensure batch traceability for diverse applications. Contact the team today.

Elastomers serve as excellent sealants in various scenarios, yet not all types are universally applicable. Certain applications, such as those involving steam in the chemical processing and Food and Pharma industries, demand specialised solutions due to the unique impact of steam on seals.

Specialist Steam Resistant O Rings

Glyon Bio Line Gaskets – Exceptional sealing performance for Pharmaceutical and Food and Beverage processing processes and applications.

Benefits of Glyon Bio-Line Gaskets include:

- Excellent chemical resistance.

- Wear-resistant and low friction.

- SIP/CIP compatible.

- Useable under high pressure and in an extreme vacuum.

- Very suitable for high circumferential speed.

- Temperature resistant from -90 °C up to +260 °C.

- EN 1935/2004 certificate.

- Good dry running capability.

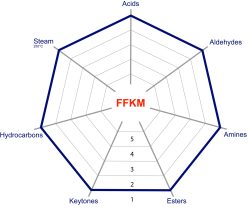

Perfluoroelastomer / FFKM O Rings – Outstanding performance in demanding operating environments.

Typical applications for Perfluoroelastomer O Rings include the Chemical, Aerospace, Oil and Gas, High Vacuum Technology, and Semiconductor industries.

And M Barnwell Services’ Perfluoroelastomer O Rings stand apart because:

- Manufacturing lead times are the shortest in the industry.

- Technical support and advice.

- Material testing and analysis.

- Material innovations such as the range of unique Perfluoroelastomers provide the low-temperature capability of any FFKM down to -46°C (-51°F).

- International Delivery.

- 72 Hour delivery on British Standard BS1806 FFKM range (Temperature -25°C, +270°C).

FFKM’s are available in Perlast®, Simriz™, Elast-O-Lion®, Parofluor®, Kalrez®, Chemraz®, Isolast®, Ekraz®, Kaflon™ and Valqua (Armor, Fluoritz). Technical data sheets will accompany your sealing product and for a detailed list of genuine manufacturer grades and compounds click here.

The Impact of Steam on Seals

When temperatures surpass 100°C, EPDM seals deteriorate rapidly. In instances of dry heat above 100°C (212°F), there is a sudden, significant decrease in both integrity (retained tensile) and extensibility (retained elongation).

However, there are some specialised EDPM solutions to consider:

- EPDM Peroxide Cured: Usable for hot water, steam, alcohols, ketones, engine coolants, organic and inorganic acids, and bases. Not resistant to mineral oils, greases, and fuels. For maximum temperatures of +150°C.

- EPDM Sulphur Cured: Inexpensive material for normal use, maximum temperature of +120°C.

This is because extended exposure to high-temperature steam can render certain elastomers brittle and prone to fracturing over time, leading to the development of cracks and subsequent leaks in seals. These leaks not only pose significant safety risks but also curtail operational efficiency.

Addressing leaks in CPI or similar applications often leads to equipment damage, impaired performance, heightened worker and environmental hazards, and necessitates system downtime for maintenance, causing substantial revenue loss. The heat and pressure involved can also inflict harm on the associated infrastructure. The potential for environmental harm and resulting expenses must also be taken into account.

Avoiding Seal Failure

It is crucial to evaluate three key factors when choosing a seal for any given application to prevent the situation described above.

- The operational temperature range of the seal: Cold temperatures reduce flexibility and elastomeric properties, while excessive heat can lead to irreversible hardening and brittleness. Potential failure at either temperature extreme must be assessed, taking into account the material’s performance under specific application conditions.

- The pressure range faced by the seal: Elevated pressures may lead to gas absorption within the material, potentially resulting in damage due to rapid gas decompression (RGD). While the controlled release of absorbed gases can avert RGD, a quick material expansion might still trigger ruptures. Employing specialised elastomer compounds is advisable to minimise the likelihood of RGD or explosive decompression.

- The fluid environment, including steam, that the seal will face: Although addressing volume changes due to swelling might be feasible, these alterations can significantly impact the seal material. Compatibility issues or swelling with operational fluids or steam can induce material softening or brittleness, both of which can ultimately lead to seal failure.

Alternative Steam Resistant O Rings and Materials

We have many types of steam-resistant seals available. Contact the team for more information.

We also offer a comprehensive range of other quality FFKM materials including Perlast®, Simriz™, Elast-O-Lion®, Parofluor®, Kalrez®, Chemraz®, Isolast®, Ekraz®, Kaflon™ and Valqua (Armor, Fluoritz). Visit the FFKM material page to learn more.

If you would like more information about our range, contact the team.

Explore the provided links for precise technical information to guide your fluid sealing choices:

- ISO3601 (BS1806) Imperial Range

- Metric Range

- BS4518 Metric Range

- O Ring Quality Standards

- Specialist Oilfield Elastomers

- FFKM Materials

If you are technical and understand your requirements please use the RFQ Form.

You Are In Safe Hands

As a reliable partner to global OEM manufacturers, M Barnwell Services ensures quality products and an exceptional service experience. With £5.1 million in sealing inventory and five UK branches strategically positioned, we’re primed to meet and surpass your needs.