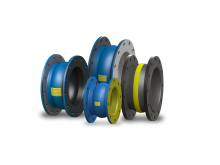

Rubber Expansion Seals

M Barnwell Services Rubber Expansion Seals offer exceptional reliability, performance, and service life.

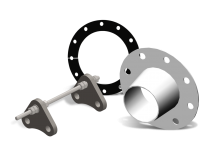

M Barnwell Services offers a variety of different rubber expansion seals, also known as rubber expansion joints, as well as accessories (UV protection panels/flange protection hoods, etc.) that are specifically engineered for the movements and vibrations in piping systems.

The Rubber Expansion Seal range will:

- Enhance thermal stability.

- Relieve system strain because of thermal change, load stress, pumping surges, and wear of settling.

- Compensate for misalignment.

- Eliminate electrolysis between dissimilar metals.

- Lower mechanical noise.

- Absorb movement and vibration.

Applications within piping systems include Axial Movement, Lateral Movement, Angular Movement, Torsional Movement, and Vibrations / Oscillations / Noises.

All of our Rubber Expansion Seals carry safety ratings that exceed product specifications in areas such as pressure and movement. Non-metallic expansion seals and flexible couplings are ideally suited for a wide variety of industries including petrochemical, offshore drilling, water and gas, compressor pump and valve, food, and manufacturing.

Types of Rubber Expansion Seals we offer:

Unsure of what you require?

M Barnwell Services takes a proactive approach to develop specific solutions for all customers. As the UK’s leading manufacturer, stockist, and distributor of fluid sealing products we have built a reputation as an industry specialist. Available to consult onsite we can offer low to high to extreme volumes and have become the go-to supplier for highly detailed and complex profiles.

Materials

Selecting the right rubber for the media and environmental conditions is critical for the expansion seal to function efficiently. Below is an overview of the materials on offer for specific applications.

Chemical Applications

- FLUOROELASTOMERS (FKM) – Temperature Range: -10°F (-23°C) to 400°F (205°C)

- HYPALON (CSM) – Temperature Range: -30°C (-34°C) to 250°F (120°C)

- EPDM – Temperature Range: -67°F (-55°C) to 300°F (150°C)

Abrasive Applications

- NATURAL RUBBER – Temperature Range: -75°F (-24°C) to 180°F (80°C)

- ABRA-LINE® – Temperature Range: -94°F (-70°C) to 180°F (80°C)

- ABRA-SHIELD™ – Temperature Range: -83°F (-64°C) to 300°F (150°C)

Food Applications (FDA)

- FDA EPDM (WHITE) – Temperature Range: -67°F (-55°C) to 300°F (150°C)

- FDA NITRILE (WHITE) – Temperature Range: -30°F (-34°C) to 250°F (120°C)

- FDA NEOPRENE (WHITE) – Temperature Range: -25°F (-32°C) to 250°F (120°C)

Oil & Gas Applications

- HNBR – Temperature Range: -83°F (-64°C) to 300°F (150°C)

- NITRILE (BUNA-N) – Temperature Range: -30°F (-34°C) to 250°F (120°C)

General Service

- CHLOROBUTYL – Temperature Range: -40°F (-40°C) to 250°F (120°C)

- NEOPRENE (CHLOROPRENE) – Temperature Range: -25°F (-32°C) to 250°F (120°C)

Reinforcing Materials

- POLYESTER – Temperature Range: to +250°F (120°C)

- NYLON TIRE CORD – Temperature Range: to +250°F (120°C)

If you would like more information about the range, material resistance, or product detail contact a member of the team.