Rubber Element Vaned Mounts

Embrace the Calm with Rubber Element Vaned Mounts

KPR11035V4M12 Datasheet

Elevate your equipment’s stability and performance with our Rubber Element Vaned Mounts, featuring a specialised rubber element with four vanes designed to provide maximum vibration isolation.

These mounts redefine industry standards with a compact design, incorporating an inbuilt bump and rebound control feature for precise regulation of equipment movement during transit.

Key Features of Rubber Element Vaned Mounts:

- Specialised Rubber Element with 4 Vanes:

– The distinctive rubber element of these mounts features four vanes, strategically designed to deliver maximum vibration isolation.

– This innovative design ensures superior performance in minimising the impact of vibrations across a range of applications. - Compact Design with Bump and Rebound Control:

– These mounts boast a compact design, complemented by an inbuilt bump and rebound control feature.

– This design element provides precise control over equipment movement during transit, ensuring stability and protection. - Dome-Shaped Metal Cap for Elastomer Protection:

– A dome-shaped metal cap shields the elastomer against splashes of oil and fuel contamination.

– This protective feature enhances the durability and longevity of the mount, even in challenging industrial environments. - Compression Design for Airborne Noise Elimination:

– The compression design, coupled with the metal cap, effectively eliminates airborne noise, presenting a superior alternative to traditional spring mountings.

– This feature ensures a quieter operational environment, particularly crucial in noise-sensitive applications. - Low Height Captive Mounting for Versatility:

– Characterised by a low-height captive mounting design, these mounts are capable of accommodating equipment loads ranging from 25kg to 85kg.

– This versatility ensures their applicability across a diverse spectrum of equipment and operational scenarios. - Natural Frequency of 8Hz:

– With a natural frequency of 8Hz, Rubber Element Vaned Mounts are finely tuned to provide optimal vibration isolation across various frequencies.

Applications:

Explore the wide-ranging applications of Rubber Element Vaned Mounts:

- Static and Mobile Generator Sets:

– These mounts find optimal use in static and mobile generator sets, ensuring maximum vibration isolation for enhanced performance. - Light Fans and Blowers:

– In applications involving light fans and blowers, Rubber Element Vaned Mounts contribute to a stable and vibration-free operational environment. - Electronic Control Panels:

– Electronic control panels benefit from the precise control over movement, reducing the risk of damage during transit. - Light Pumps and Compressors:

– Ideal for use in light pumps and compressors, these mounts provide effective vibration isolation, promoting smooth and reliable operation. - Railroad Equipment Compartments:

– In railroad equipment compartments, where stability is paramount, Rubber Element Vaned Mounts excel in minimising vibrations for passenger comfort.

In summary, Rubber Element Vaned Mounts stand as a testament to innovation in vibration isolation technology. Their specialised rubber element, compact design, and versatile load-bearing capacity make them an indispensable choice across a broad spectrum of applications, ensuring enhanced stability and performance for your equipment.

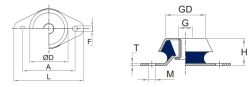

Dimensions in millimeters (mm)

| Part Number | L | H | A | F (M) | D | GD | S | G |

|---|---|---|---|---|---|---|---|---|

| KPR11035V4 | 110 | 35 | 73-90 | 8.3*16 | 65 | 50 | 3.0 | M12 |

Max load / Max deflection

| Part Number | 45 ShA | 60 ShA | 70 ShA | |||

|---|---|---|---|---|---|---|

| Max Load (kg) | Deflection (mm) | Max Load (kg) | Deflection (mm) | Max Load (kg) | Deflection (mm) | |

| KPR11035V4 | 25 | 4.0 | 60 | 4.0 | 85 | 4.0 |

To find out more about our Anti-Vibration Mounts, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.