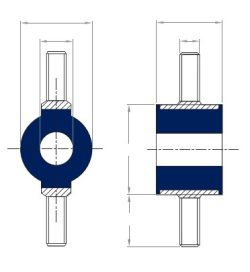

O Type Low Frequency Mount

O Type Low-Frequency Mount: Damping the Disturbance, Elevating the Ease

The O Type Mount is intricately designed to excel in effectively damping vibrations across compression, shear, and lateral modes. Its outstanding performance is particularly noteworthy in applications characterised by low-frequency vibrations, where its strategic design ensures optimal vibration control.

Key Features:

- Comprehensive Vibration Damping: The design of this mount is geared towards damping vibrations not only in compression but also in shear and lateral modes. This comprehensive approach enhances its effectiveness in diverse vibration scenarios.

- Exceptional Low-Frequency Performance: The mount stands out for its exceptional performance, especially in applications featuring low-frequency vibrations. Its ability to address these specific vibration characteristics makes it a reliable choice for a range of scenarios.

Applications:

The versatility of the O Type mount extends to various applications, including:

- Lightweight Electronic Equipment: The O Type mount is well-suited for supporting lightweight electronic equipment, providing a stable environment to minimize vibrations and ensure optimal performance.

- Suspension of Lightweight Cameras: In applications involving lightweight cameras, the mount’s strategic design contributes to effective vibration damping, ensuring steady and shake-free operation.

- Packaging Delicate Equipment: The mount finds valuable application in packaging delicate equipment, where it aids in maintaining the integrity of fragile components by minimising vibrations during transit.

- Light Pumps and Electric Motors: For light pumps and electric motors, the O Type mount offers reliable vibration damping, promoting smooth and stable operation.

Conclusion

In summary, the O Type mount is not only strategically designed for comprehensive vibration-damping but also excels in low-frequency scenarios, making it a versatile solution for applications ranging from lightweight electronic equipment to delicate packaging needs.

Max shear load in kilograms (kg)

| Part Number | Dimensions (mm) | 45 ShA | 60 ShA | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| D | H | W | F | G | L | Max Shear | Defin. | Max Shear | Defin. | |

| O1212M4 | 12.5 | 12.5 | 9.5 | 5.6 | M4 | 10 | 0.006 | 1mm | 0.12 | 1mm |

| O1417M4 | 14.0 | 17.0 | 13.0 | 6.0 | M4 | 10 | 0.10 | 1mm | 0.20 | 1mm |

| O2530M6 | 25.0 | 30.0 | 20.0 | 12.0 | M5 | 14 | 0.15 | 1mm | 0.35 | 1mm |

| O3640M10 | 36.0 | 40.0 | 26.0 | 17.0 | M10 | 20 | 0.32 | 1mm | 0.64 | 1mm |

Max compression and lateral load in kilograms (kg)

| Part Number | 45 ShA | 60 ShA | ||

|---|---|---|---|---|

| Max Compression | Max Lateral Load | Max Compression | Max Lateral Load | |

| O1212M4 | 0.6 | 0.20 | 0.5 | 0.3 |

| O1417M4 | 1.3 | 0.4 | 1.0 | 0.5 |

| O2530M6 | 2.8 | 1.0 | 1.5 | 0.8 |

| O3640M10 | 8.0 | 3.0 | 2.4 | 1.2 |

To find out more about our Anti-Vibration Mounts, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.