Lithography Machine Seals

Lithography Machine Seals – Specialised Seals to Protect You and Your Machines

M Barnwell Services is one of the UK’s leading stockists and distributors of Semiconductor seals and can provide specialist Lithography Machine Seals to meet all internal applications. With over £5.1 million in stock, we serve over 5000 global customers with swift and dependable deliveries.

Our proficient team manages the entire production process, from prototyping and testing to final part manufacturing. Additionally, we offer specialised certification upon request.

If you would like more information about our range visit the Semiconductor Overview Products page or contact a team member.

Lithography Machines require fluid sealing to precisely control the movement of fluids like photoresists, developers, and cleaning solutions. This sealing ensures accurate delivery, prevents contamination, maintains consistent process conditions, and supports chemical compatibility.

It also helps optimise resource use and process efficiency, all of which are vital for reliable semiconductor manufacturing.

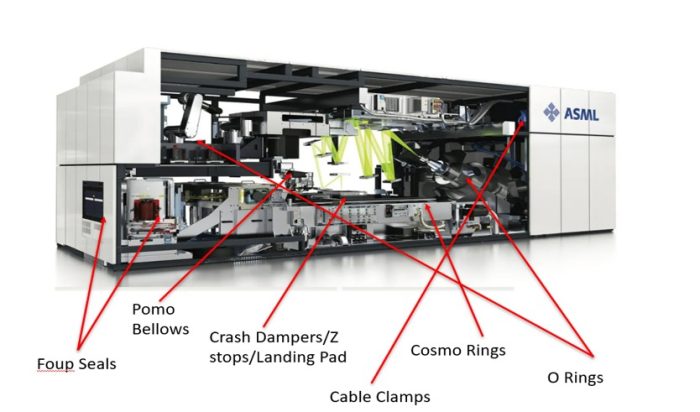

Types of Lithography Machine Seals

FOUP Seals

Lithography Machines use FOUP seals to maintain a controlled environment and prevent contamination during semiconductor wafer handling and storage. These seals protect wafers from particles, moisture, and environmental factors that could harm semiconductor manufacturing quality.

FOUP seals play a critical role in preserving the purity and integrity of the wafers, which is essential for achieving high-performance semiconductor devices.

To see how our FOUP seals perform, read our FOUP Door Seals case study.

Pomo Bellows

In Lithography Machines, Pomo Bellows find primary application in preventing contamination and upholding a controlled environment. These bellows, made from specialised materials, create flexible barriers that protect sensitive components and mechanisms from airborne particles, dust, and other contaminants.

By encapsulating critical parts, they ensure a clean and controlled environment within the Lithography Machine. This is essential to achieve high-precision patterning on semiconductor wafers, as even tiny contaminants can disrupt the intricate processes involved.

Pomo Bellows contribute to the overall reliability, accuracy, and yield of semiconductor manufacturing in Lithography Machines.

Crash Dampers/Z Stops/ Landing Pads

Lithography Machines employ Crash Dampers, Z Stops, and Landing Pads to prevent damage and ensure controlled motion.

These components serve different but complementary purposes:

- Crash Dampers:

– Crash Dampers are engineered to absorb kinetic energy and offer a cushioned halt when moving parts or stages approach their end positions with excessive speed or force.

– In Lithography Machines, where precision is paramount, Crash Dampers prevent abrupt collisions that could lead to mechanical stress, misalignment, or damage to sensitive components. - Z Stops:

– Z Stops are mechanical or electronic limit switches that define the upper and lower travel limits of a moving component along the Z-axis (vertical direction).

– In Lithography Machines, they ensure that moving stages or parts do not exceed safe operational boundaries, preventing collisions, and safeguarding the machine’s structural integrity. - Landing Pads:

– Landing Pads are created to furnish a secure and controlled surface for moving stages or components to rest on. They prevent impact damage when stages or parts require accurate positioning or parking.

– This is particularly important in Lithography Machines, where precise positioning is critical to achieving accurate patterns on semiconductor wafers.

Collectively, Crash Dampers, Z Stops, and Landing Pads contribute to the safe operation, protection of components, and preservation of precision within Lithography Machines.

These mechanisms minimise the risk of unintended collisions, mechanical stress, and damage, ensuring consistent and reliable semiconductor fabrication processes.

Cable Clamps

Cable clamps are used in Lithography Machines to manage, protect, and organise cables. They prevent cable damage, maintain signal integrity, avoid interference, enhance safety, provide accessibility for maintenance, and contribute to a clean environment.

Additionally, cable clamps help ensure the durability and reliability of cables within the machine’s intricate setup.

Cosmo Rings

Cosmo Rings, or cosmetic rings, are used in Lithography Machines to ensure precise alignment and consistency in manufacturing. They fine-tune component positioning, compensate for variations, dampen vibrations, and contribute to overall stability.

Cosmo Rings play a pivotal role in achieving accurate patterns on semiconductor wafers by maintaining uniformity and optimal optical performance.

O Rings

O Rings find use in Lithography Machines to create reliable seals, preventing leaks in fluid and gas systems. They ensure chemical compatibility, resist temperature and pressure variations, fit into tight spaces, and contribute to contamination prevention.

By offering versatility and reducing maintenance needs, O Rings play a crucial role in maintaining the precision and reliability of these complex machines.

To explore our range of O Rings further, click here.

You Are In Safe Hands

As a trusted supplier to leading global OEM manufacturing companies, M Barnwell Services is committed to providing superior products and an exceptional level of service that rivals, if not surpasses, all others.

With a sealing inventory exceeding £5.1 million and supported by five strategically located branches throughout the UK, we are perfectly positioned to meet your requirements and strive to exceed your expectations.

For further details about our offerings, access our catalogue or contact a member of the team.

E&OE