KMR Marine Mounts

KMR Marine Mounts: Navigating Smooth Seas of Stability

Our purpose-built KMR Marine Engine Mounts are meticulously designed for the installation of marine engines that generate propeller thrust. Beyond marine applications, these mounts are a trusted choice to minimise vibrations in both mobile and stationary machinery.

Key Features of KMR Marine Mounts:

- Specialised Design for Marine Engines:

– The KMR Mount is purpose-built for marine engines, specifically those generating propeller thrust.

– Its design is tailored to withstand the unique challenges posed by maritime environments, providing stability and reliability for marine propulsion systems. - Metal Top Cover for Element Protection:

– A metal top cover is integrated into the design to protect the rubber element from contamination, particularly from oil and diesel fuel.

– This protective feature enhances the longevity of the mount, ensuring consistent performance even in harsh marine conditions. - Built-in Bump and Rebound Control:

– The KMR Mount features a built-in bump and rebound control feature, providing precise regulation of equipment movement during transit.

– This control feature enhances stability, particularly in dynamic marine environments where constant motion is prevalent. - Optimised Stiffness Characteristics:

– With 50% lower stiffness across the mount concerning vertical stiffness, these mounts offer optimised characteristics for effective vibration isolation.

– The longitudinal stiffness is 2.5 times the vertical stiffness, making it suitable to absorb engine thrust in marine applications.

Applications:

Discover the extensive applications of KMR Marine Engine Mounts:

- Static and Mobile Generator Sets:

– KMR Mounts are an ideal choice for static and mobile generator sets, providing stable support and minimising vibrations for efficient power generation. - Pumps:

– In pump applications, these mounts contribute to a vibration-free environment, ensuring smooth and reliable pump operation. - Compressors:

– For compressors, KMR Mounts play a crucial role in vibration isolation, promoting efficiency and longevity in compressor systems. - Marine Engines (Refer to Technical Data for Mounting Thrust and Bolt Fixing):

– Specifically designed for marine engines generating propeller thrust, these mounts are a key component in maritime propulsion systems.

– Refer to technical data for precise information on mounting thrust and bolt fixing, ensuring optimal performance in marine applications.

Conclusion

In summary, KMR Marine Engine Mounts stand as a reliable and purpose-built solution for the challenges posed by marine environments. Whether in marine propulsion systems, generators, pumps, or compressors, these mounts provide essential stability, minimising vibrations and ensuring the longevity of your equipment.

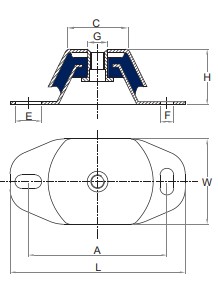

Dimensions in millimeters (mm)

| Part Number | A | L | W | C | E | F | G | H |

|---|---|---|---|---|---|---|---|---|

| KMR23070 | 182 | 230 | 112 | 80 | 35 | 18 | M20 | 73 |

| KMR18350 | 140 | 183 | 75 | 75 | 20 | 13 | M16 | 50 |

| KMR12040 | 100 | 120 | 60 | 60 | 11 | 11 | M12 | 40 |

Vertical Static Load

| Part Number | 45 ShA | 55 ShA | 65 ShA | 75 ShA | ||||

|---|---|---|---|---|---|---|---|---|

| Max Load (kg) | Deflection (mm) | Max Load (kg) | Deflection (mm) | Max Load (kg) | Deflection (mm) | Max Load (kg) | Deflection (mm) | |

| KMR23070 | 350 | 5 | 520 | 5 | 800 | 5 | 1000 | 5 |

| KMR18350 | 150 | 5 | 210 | 5 | 300 | 5 | 450 | 5 |

| KMR12040 | 50 | 4 | 65 | 4 | 100 | 4 | - | - |

To find out more about our KMR Marine Mounts and to view their Technical Data, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.