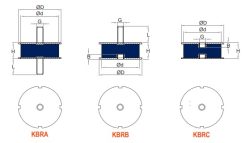

KBR Compactor Mounts

Silence the Shake, Amplify Efficiency with KBR Compactor Mounts

Our KBR Compactor Mounts offer a solution tailored for applications subject to substantial torsion and shear stress during operation. These mounts are engineered with precision to excel in environments where equipment undergoes significant mechanical forces. Explore the distinctive features and targeted applications that position KBR Mounts as the ideal choice for optimising torsion and shear stability.

Key Features of KBR Compactor Mounts:

- Notched Metal Discs for Rotation Prevention:

– KBR Mounts feature notches in the metal discs, strategically designed to prevent rotation during operation.

– This unique feature enhances their stability, ensuring reliable performance in applications with pronounced torsional and shear stress. - Dynamic Shear Deflection Capability:

– These mounts boast a dynamic shear deflection capability, accommodating up to 5mm peak to peak.

– This remarkable flexibility ensures adaptability to varying operational conditions, maintaining stability during dynamic forces.

Applications:

Discover the versatile applications of KBR Compactor Mounts:

- Compactor Plates:

– Specifically well-suited for compactor plates, KBR Mounts provide robust stability in environments where equipment encounters significant torsion and shear stress. - High Shear Applications:

– Excelling in high shear applications, these mounts contribute to stability, minimising the impact of dynamic forces and promoting efficient equipment operation. - Vibratory Screens:

– In vibratory screens, KBR Mounts play a crucial role in optimising torsion and shear stability, ensuring smooth and reliable screening processes.

In summary, KBR Compactor Mounts emerge as a specialised solution, addressing the challenges posed by significant torsion and shear stress in diverse industrial applications. With notched metal discs and dynamic shear deflection capabilities, these mounts offer a robust foundation for equipment subjected to dynamic forces, making them an ideal choice for compactor plates, high-shear applications, and vibratory screens.

Dimensions in millimeters (mm)

| Part Number | B | D | d | H | G | L | Plate Thickness |

|---|---|---|---|---|---|---|---|

| KBRA10540 | 18 | 105 | 93 | 40 | M16 | 41 | 3 |

| KBRB10540 | 18 | 105 | 93 | 40 | M16 | 41 | 3 |

| KBRC10540 | 18 | 105 | 93 | 40 | M16 | - | 3 |

| KBRA10555 | 18 | 105 | 93 | 55 | M16 | 41 | 3 |

| KBRB10555 | 18 | 105 | 93 | 55 | M16 | 41 | 3 |

| KBRC10555 | 18 | 105 | 93 | 55 | M16 | - | 3 |

| Part Number | Maximum Compression Load | Maximum Shear Load | ||

|---|---|---|---|---|

| 45 ShA | 60 ShA | 45 ShA | 60 ShA | |

| KBR10540 | 300 | 560 | 80 | 150 |

| KBR10555 | 180 | 340 | 50 | 100 |

To find out more about our Anti-Vibration Mounts, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.