Heavy-Duty KMR Marine Engine Mount

Powering Your Journey with Unwavering Stability

KMR330112 Datasheet

The KMR330112 Marine Engine Mount is meticulously engineered for exceptional performance in diverse applications. This mount, designed with precision and durability in mind, boasts a range of features tailored to ensure optimal functionality and longevity. Explore the key features and versatile applications that position the KMR330112 as a standout choice for equipment stability.

Key Features:

- Large Top Cover Plate for Element Protection:

– The KMR330112 Mount features a spacious top cover plate. Ultimately providing robust protection for the rubber elastomer against oil and diesel fuel contamination.

– This protective feature enhances the durability and consistent performance of the mount, ensuring reliability in challenging operational environments. - Heavy-Duty Fixing Holes for Maximum Flange Strength:

– Engineered with heavy-duty fixing holes, this mount offers maximum flange strength. This ensures a secure and stable connection between the mount and the equipment.

– The design prioritises durability, contributing to the overall load-bearing capacity and longevity of the mount. - Robust Load Rating Range:

– With a load rating ranging from 350kg to 1600kg, the KMR330112 Mount is designed to handle a broad spectrum of loads with ease.

– This robust load rating makes it a versatile solution suitable for various applications, ensuring stability and performance under varying conditions. - Built-in Bump and Rebound Control:

– The KMR330112 Mount is equipped with a built-in bump and rebound control feature, strategically limiting the movement of equipment during transit.

– This control mechanism enhances stability, particularly in scenarios where constant motion is a consideration.

Applications:

Discover the diverse applications of the KMR330112 Marine Engine Mount:

- Generators: The KMR330112 Mount provides optimal stability for generators, minimizing vibrations and ensuring reliable power generation.

- Compressors: In compressor applications, this mount plays a crucial role in vibration isolation, contributing to the efficiency and longevity of compressor systems.

- Pumps: For pump applications, the KMR330112 Mount contributes to a vibration-free environment, ensuring smooth and reliable pump operation.

- Conventional Engines: Suitable for a range of conventional engines, this mount offers stable support and minimises vibrations for enhanced engine performance.

- Marine Engines (Longitudinal Propeller Thrust Requirement): Specifically designed to meet the requirement of withstanding longitudinal propeller thrust in marine engines, the KMR330112 Mount is a reliable choice for marine propulsion systems.

In summary, the KMR330112 Marine Engine Mount stands as a robust and versatile solution for optimal equipment stability. Whether in generators, compressors, pumps, conventional engines, or marine propulsion systems, this mount delivers the durability and performance needed for demanding operational environments.

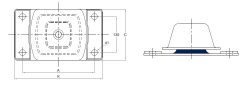

Dimensions in millimeters (mm)

| Part Number | A | Top Cover Sitting Width | C | K | Free Height | d1 | Top Cover Fixing Bolt Hole | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| KMR330112 | 270 | 146 | 192 | 331 | 112 | 22 | M24 | 10 |

| Part Number | 45 ShA | 60 ShA | 70 ShA | |||

|---|---|---|---|---|---|---|

| Max Load (kg) | Max Longitudinal Thrust (N) | Max Load (kg) | Max Longitudinal Thrust (N) | Max Load (kg) | Max Longitudinal Thrust (N) | |

| KMR330112 | 650 | 5250 | 950 | 7200 | 1600 | 13000 |

To find out more about our Anti-Vibration Mounts, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.