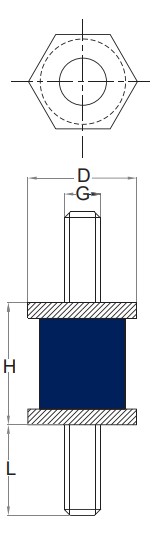

AH Hexagonal Mount

Securing Stability, Defying Disturbance – AH Hexagonal Mount

The AH Hexagonal Mount is meticulously engineered to alleviate torsional stress on the rubber during the installation process. A distinctive feature of these mounts is the inclusion of a hexagonal metal plate, offering convenience for installers by allowing the use of a standard spanner. This not only simplifies the installation process but also enhances the overall stability of the mount.

Key Features of the AH Hexagonal Mount:

- Efficient Tightening Mechanism: The hexagonal metal plate serves a dual purpose by providing a secure point for tightening the mount using a spanner. This ensures a robust and reliable installation.

- Material Versatility: Standard mounts are crafted using natural rubber, known for its excellent vibration absorption properties. However, the flexibility extends to the availability of other rubber compounds to meet specific application requirements.

- Customisation Options: Mounts with a female thread are available upon request, allowing for tailored solutions based on unique installation needs.

Applications:

Hexagonal mounts find versatile applications across various settings, including:

- Instrument Panels: The AH Hexagonal Mount is well-suited for supporting instrument panels, ensuring stability and minimising vibrations for accurate readings.

- Engine Radiators: In engine systems, these mounts prove effective in supporting radiators, contributing to their stability and longevity.

- Conveyors and Hoppers: For machinery involving conveyors and hoppers, hexagonal mounts provide reliable support, reducing torsional stress during operation.

- Small Generators: Ideal for small generators, these mounts contribute to stable operation by alleviating torsional stress during installation.

- Fans and Compressors: The versatility of hexagonal mounts extends to applications involving fans and compressors, where their design helps maintain operational stability.

In summary, the thoughtful engineering of hexagonal mounts addresses torsional stress concerns during installation, making them a reliable choice for diverse applications, from instrument panels to fans and compressors.

Max compression and shear load in kilograms (kg)

| Part Number | Bolt Size | 45 ShA | 60 ShA | ||

|---|---|---|---|---|---|

| ØD x H | G x L (mm) | Compression | Shear | Compression | Shear |

| AH1516M6 | M6 X 15 | 3.75 | 1.1 | 6.7 | 2 |

| AH2119M6 | M8 X 20 | 8 | 3.3 | 14 | 6 |

| AH2927M8 | M8 X 17 | 14 | 5.8 | 25 | 10 |

| AH2923M8 | M8 X 20 | 16 | 6.4 | 32 | 12 |

| AH3226M8 | M8 X 16 | 16 | 6.2 | 30 | 11 |

| AH3222M8 | M8 X 20 | 30 | 12 | 60 | 22 |

| AH3322M10 | M10 X 25 | 30 | 12 | 60 | 22 |

| AH4225M10 | M10 X 30 | 55 | 26 | 110 | 47 |

To find out more about our Anti-Vibration Mounts, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.