Astra Seal Fitting Guide

An important part to making sure the Astra Seal® works at its best capacity, is to make sure the installation of the seal is done correctly. Anyhow, errors happen during installation of the seal, which leads to failure, no matter what the quality of the seal was in the first place.

Lubrication

It is recommended that lubrication is used when installing Astra Seals® wherever possible. This can be applied to the seal and the housing prior to assembly. It will aid assembly and will lower the risk of damage to the seal jacket.

Certain lubrications such as Vacuum grease type products will also improve seal performance when sealing against gasses, and special type lubricants such as Apiezon N will improve seal performance at Cryogenic temperatures. Below are some suggested products but always check the datasheets to ensure they are suitable for your particular application.

Recommended Lubricants:

- Apiezon N

- Krytox Lvp

- Rocol Foodlube Ptfe Fluid

- Dow Corning Silicone High Vacuum Grease

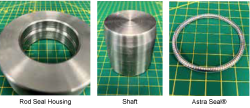

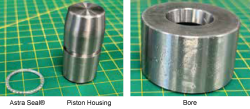

Rod Seal Components

Housing Requirements / Recommendations

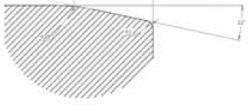

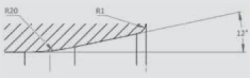

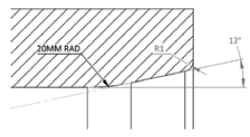

Lead In Chamfer

A lead in chamfer is required on the shaft, this is to ensure a gradual compression of the seal which reduces the risk of jacket damage.

This chamfer needs to be <15° with the optimum angle being 12°.

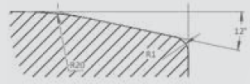

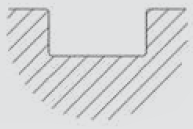

Groove

Before fitting an Astra Seal® ensure the groove is free from any sharp edges, damage or FOD. Ensure the finish of all sealing surfaces are as smooth as possible with recommended finish of at least .4Ra.

STEP 1: Rod seal

To begin fitting the Astra Seal®

- *Apply lubrication to the seal & housing

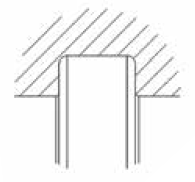

- Insert the seal into the bore passing the leading edge of the Astra Seal® past the groove as shown

*Where application allows

STEP 2: Rod Seal

- Locate the trailing edge of the seal in the groove

- Once pressed in firmly, pull back the leading edge of the seal and it will snap into place

Step 3: Rod Seal

- *Lubricate the shaft ready to be installed into the bore

- Insert the shaft into the bore ensuring the lead in chamfer is in first. Use a press to install the shaft wherever possible to ensure even distribution of force.

* Where application allows

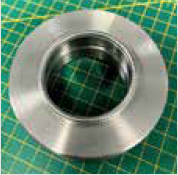

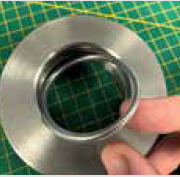

Fitted Astra Seal®

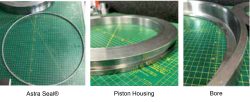

Piston Seal Components

Housing Requirements / Recommendations

Lead In Chamfer – Bore

A lead in chamfer is required in the bore, this is to ensure a gradual compression of the seal which reduces the risk of jacket damage.

This chamfer needs to be <15°, with the optimum angle being 12°.

Lead In Chamfer – Piston

A lead in chamfer is required when fitting the Astra Seal® into its groove to allow gradual stretching of the seal.

Groove

Before fitting an Astra Seal®, ensure the groove is fee from any sharp edges, damage or FOD.

Ensure the finish of all sealing surfaces are as smooth as possible with a recommended finish of at least .4Ra.

STEP 1: Small Diameter Piston Seal

- *Apply lubrication to the seal & housing

*Where application allows

STEP 2: Small Diameter Piston Seal

- Place the Astra Seal® onto the lead in chamfer on the shaft. Note; The next step can be done by hand or by using a press.

By hand;

- Begin pushing the seal down the shaft towards the groove

- The seal will stretch over the lead in chamfer, down the shaft and snap into the groove when it reaches it

STEP 2 – Alternative Method

By press; (for a more controlled installation of the Astra Seal®)

- Place piston with the O Ring positioned on the start of the lead in chamfer onto the installation bore fixture

- Press down, the piston will slide into the bore until the O Ring snaps into the groove

STEP 3 – Small Diameter Piston Seal

- Once the seal is in the groove, the shaft can be inserted into the bore with the leading-edge chamfer contacting the seal first as shown

- This should be done on a press wherever possible

Fitted Astra Seal®

Piston Seal (Large id) Installation

Piston Seal Component

Housing Requirements / Recommendations

Lead In Chamfer

A lead in chamfer is required on the shaft, this is to ensure a gradual compression of the seal which reduces the risk of jacket damage.

This chamfer needs to be <15°, with the optimum angle being 12°.

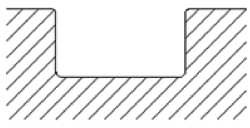

Groove

Before fitting an Astra Seal® ensure the groove is free from any sharp edges, damage or FOD.

Ensure the finish of all sealing surfaces are as smooth as possible with a recommended finish of at least .4Ra.

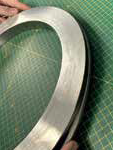

STEP 1 – Large Diameter Piston Seal

- *Apply lubrication to the seal & housing

- Begin fitting the Astra Seal® by locating the leading edge of the seal into the groove as shown

*Where application allows

STEP 2 – Large Diameter Piston Seal

- Continue pressing the seal into the groove along the length of the seal

- When the seal becomes tight, stretch the remaining portion of the seal over the lip of the housing and into the groove

- Check the seal is seated correctly

STEP 3 – Large Diameter Piston Seal

Astra Seal® Fitted into groove

STEP 4 – Large Diameter Piston Seal

- The Piston can now be installed into the bore making sure the lead in chamfer is contacting the seal first to allow gradual compression

Apiezon N

Apiezon N can contain a high molecular weight polymeric additive that allows it to form a rubbery, cushioning effect between mating surfaces. The physical nature of this product makes it a popuar grease for high vacuum use as well as general purpose laboratory use. It is not recommended for use above 30°C. Vapor pressure is estimated to be 8.10 – 10 mbar at 20°C.

When it comes to low temperature applications, nothing comes close in performance to Apiezon N Grease. The product retains most of its important properties all the way down to -269°C / 4°K.

This Lubricant solution to those low temperature challenges can also be cycled from these low temperatures up to room temperature and then back down without showing visible signs of cracking. And in addition, this grease is completely free of any silicones or halogens.

Typical static applications:

- Sensor mount within certain low temperature scientific instruments

- Thermal coupling medium with cryostats

- Use in just about any cryogenic experiments

- Sensor mount within certain low temperature scientific instruments

- Thermal coupling medium with cryostats

- Use in just about any cryogenic experiments

Krytox LVP

Krytox LVP high vacuum grease is used as a sealant or lubricant in vacuum systems. Chemically inert and offering superior lubrication properties, Krytox LVP grease combines the extremely low vapor pressure of Krytox fluorinated oil, which is based on the most stable type of perfluoroalkylpolyether available, with a fluorocarbon thickener. Thus, Krytox LVP grease will not explode, ignite, decompose, react to form gummy or solid deposits, or act as fuel for fires. It retains its lubricating ability at temperature extremes ranging from -15°C to 300°C and offers complete oxidation resistance. All these features add up to lower wear and longer life for equipment and components – so important when access for component repair or replacement is difficult or impossible.

Specifications | Units | GeminYe VAC 3 | RT 15°C | KRYTOX LVP |

| Vapor Pressure At 25°C | Mbar | 1.10-9 | 1.10-9 | 1.10-13 |

| Penetration (Worked, 25°C) | Mm/10 | 250

| 295 | 265-295 |

| Temperature Range | °C | +20/+200 | -30/+150 | -15/+300 |

| Density | g/ml | 1.92 | 1.92 | 1.94 |

| Viscosity | cSt | 1500°C at 20 °C | 1300°C at 20°C | 740°C at 40°C |

| Packaging | – | 100g | 100g | 57g |

Dow-Corning Silicone High Vacuum Grease

Silicone High Vacuum Grease is a sealant, which is ideally suited for all high vacuum applications. The grease is of uniform, soft consistency and can be used over a wide range of temperatures. Important features of this high vacuum grease include good sealing ability, excellent resistance to water, chemicals, high and low temperatures, and low volatility. This grease can be used in applications operating down to 10-8 mbar.

Specifications | DC high vacuum grease |

| Vapor Pressure At 25°C | 1.10-8 mbar |

| Colour | Light grey / translucent |

| Temperature Range | -40°C to 200°C |

| Evaporation After 24h At 200°C | < 2% |

| Packaging | 50g |

More information about our range of Astra Seals® can be found on our Extreme Pressure Seals – Astra Seals® page.

To find out more about how M Barnwell Services can assist with your extreme pressure seal requirements, please contact our specialist team. E & OE.