Types of Metal Seals

Common Types of Metal Seals

METAL O RING SEAL

Metal O Rings are a superior sealing method, these seals are created to improve the capability in intense operations. Used in many cases where elastomers don’t provide sufficient reliability for certain applications. They have the capability to withstand wide scope of temperatures, corrosive chemicals, high pressures, and radiation. Metal O Rings are commonly made from tubing. A classic tubing is made out of stainless steel and high-temperature alloys.

METAL C RING SEAL

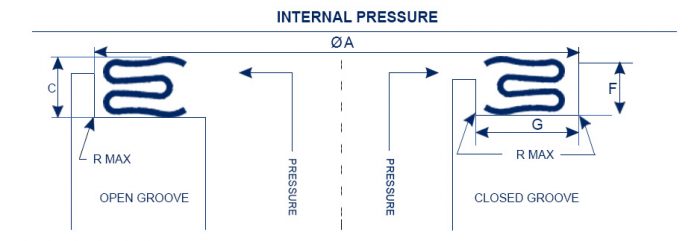

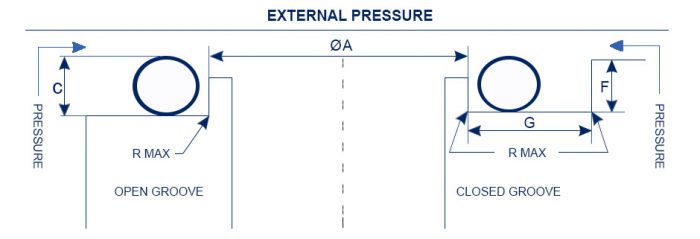

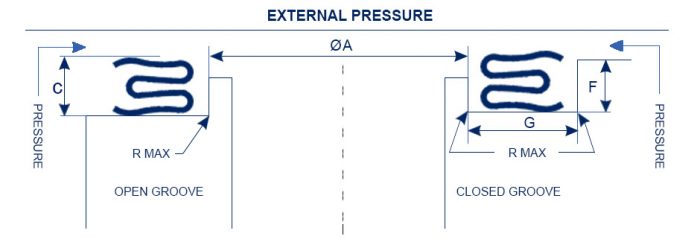

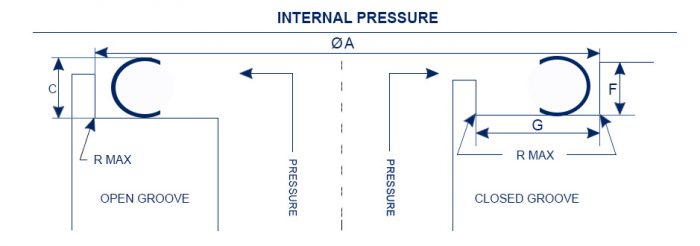

Variations and heat are a continuous worry for producers of fuel injections, valves, and aircraft engines, as the mixture of these two elements can cause problems and failure to the seal performance. C Rings are designed to defeat this issue, due to its C-shaped form it provides the high spring back features. They can be used for either internal, external or axial stresses under radical circumstances which forbid the use of gaskets designed from natural resources. The press of the seal in a supervised groove between two radial interfaces, making a counter load, providing an efficient sealing.

C Rings may be liable to a plastic distortion when fixed at the 20% press, they may be recyclable in their actual or virtually the same groove depth as the original. These seals possess a lot lower flange load than O Rings, however, it is yet high enough to ensure functional smearing of the coating and plating used on a sealing area.

METAL SPRING ENERGISED C RING SEAL

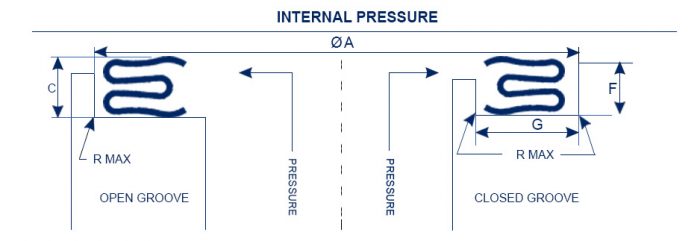

Metal Spring Energised C Ring Seals provide a broad temperature range resistance of between -253° and +1100°C. They present high pressure to 6900BAR, High Pressure – Ultra Vacuum. These seals are commonly not constrained by radiation, corrosion or any different disadvantageous environmental circumstances. They provide very high efficiency, self and stress launched design. When the seal is compressed to a previously agreed deflection, sealing pressure is launched by the flexible jacket and spring. Further seal activation is attained when system stress is initiated, enhancing seal loading. In order to provide an efficient metal anti-leak seal, Metal Spring Energised Seals use the impact of the mating elements contact areas and the system stress or vacuum. Industries served by these seals include:

- Aerospace – jet engines, high-temperature aircraft systems, instruments and controls

- Automotive – diesel engines

- Chemical Processing processes

- Petrochemical manufacturing processes

They are perfect for static or restricted rotating and reciprocating motion. The seal design and the exceptional shaping and manufacturing process ensure a metal seal that provides for contact with the dynamic sealing areas.

METAL E RING SEAL

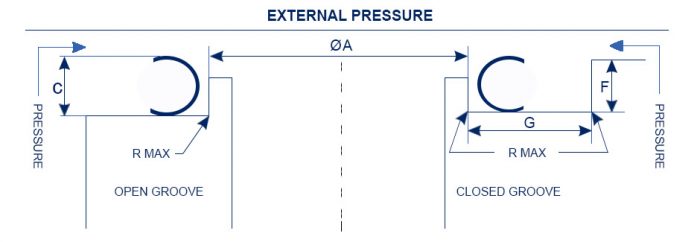

Metal E Ring Seals are designed to work in systems that demand light loading, high-temperature resistance, and flexibility. They function mainly inside the elastic restraints of the medium. The excellent spring back or elasticity features are crucial when used in grooves that withstand large quantities of the division during ordinary processes. Applications include exhaust manifold couplings, gas turbine engine housings, ball valve seat, and hot air ducting seals. this type of seal provides a very good wear resistance.

The compression load demands are relatively low with higher spring back in comparison with different metal seal types. The load demands, however, will rise equivalent to the pressure of the system, stretching the spring back ability in radical conditions. In static conditions, coating and plating present a lower sealing reinforcement due to the low power and low sealing pressure. In higher stress installations, the pressure could rise to permit the plating to smear into the cavity deficiencies. In dynamic conditions where the seal is surrendered to varying loads and groove changes, the plating will work between the seal and the groove increasing sealing and lubricating both elements.

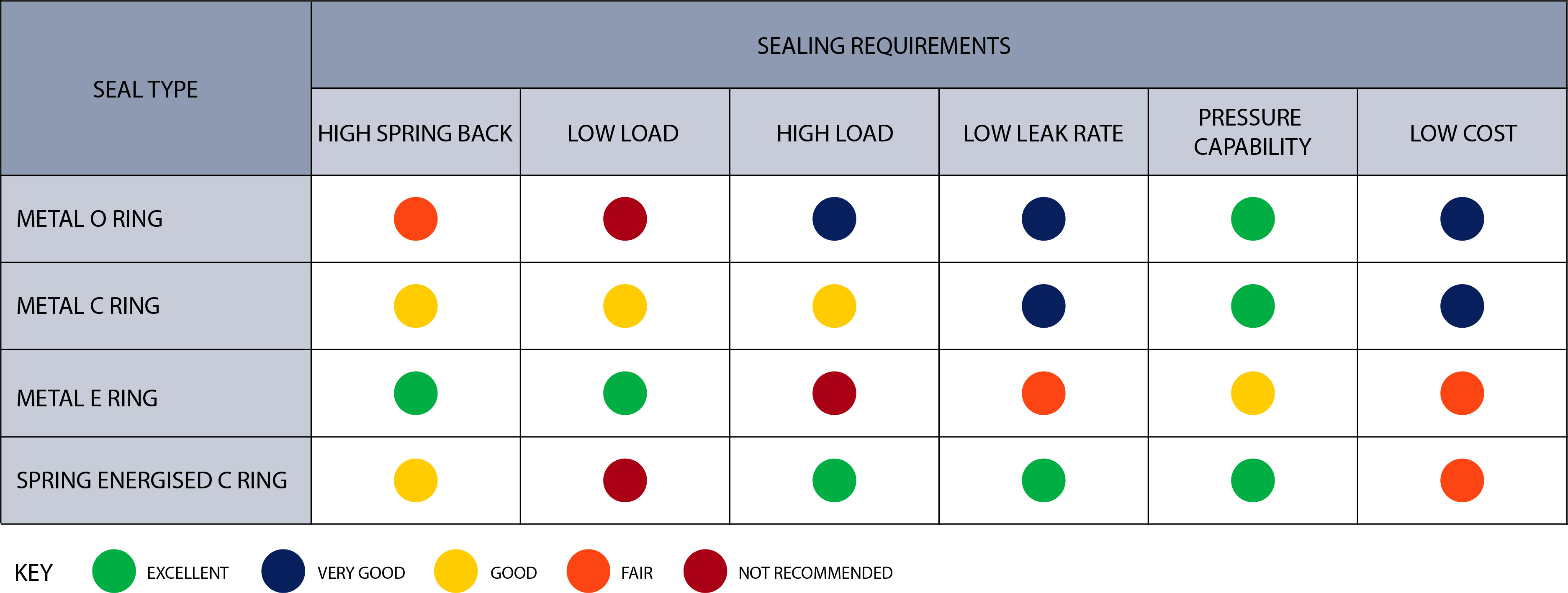

METAL SEAL SELECTION IN A NUTSHELL

For more information about Barnwell range of products click here or to download our catalogue click here. To contact us click here.

E & OE. M Barnwell Services endeavours to make sure all the content is correct. Information has been gained from manufacturing partners.