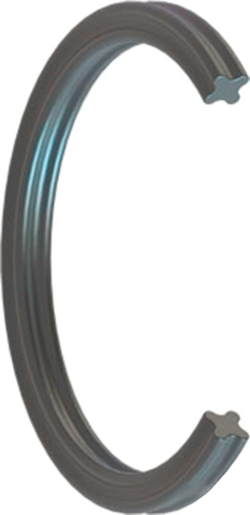

X-Ring / Quad Ring / Nu-LIP

Less friction no twist – X-Ring / Quad Ring / Nu-LIP replacement for O-Rings

M Barnwell Services X-Ring / Quad Ring / Nu-LIP are double-acting pressure seals used an alternative to O Rings. For use in reciprocating dynamic or rotary applications, where spiral twisting and rolling is a problem and are available in a variety of materials.

X-Rings are often used in applications where the seal is required to operate under low temperature and pressure conditions. High sealing efficiency can be achieved with an X-Ring as the mold parting line is not coincident with the primary sealing faces.

The high sealing efficient rings can typically be retrofitted into existing O Ring grooves, with the sizing often based around the size of the original O Ring. Unlike O Rings, the square envelope of the X-Ring stops the seal from twisting and rolling in reciprocating applications (preventing spiral failure).

X-Rings offer a reduction in friction as trapped media between the lobes can provide lubrication to the sliding sealing face. The combination of a low modulus material and small cross section can help to reduce friction in low pressure applications. In high pressure applications, selecting a higher modulus material with a reduced coefficient of friction can offer a reduction in friction.

High performance materials

M Barnwell Services supply a range of elastomer materials perfect for every application, with performance characteristics that meet high temperature, high pressure and aggressive chemical applications. We supply X-Rings that are manufactured to standard O Ring sizes, as well as custom sizes for specific applications. For use in the Food & Drink (FDA) and Pharmaceutical industries.

If you would like more information about our range, download our catalogue, visit the Seal Maker Page or contact a member of the team.