Sealing Washers

The UK’s specialist supplier of Sealing Washers

M Barnwell Services is one of the UK’s largest independent stockists and distributors of Sealing Washers and Seals. With a £5.1 million inventory, along with expert insights and 35,000 stock lines, we guarantee a tailored sealing solution for your needs.

Our offerings encompass diverse dimensions and materials, including Elastomer, Thermoplastic, Fibre, Steel, Copper, Stainless Steel, Aluminium, Brass, and Cork. Beyond this, we excel in crafting custom designs and providing specialised surface finishes to meet your unique requirements.

Types we offer:

| FLAT WASHERS Form A to G, Hardened, Chamfered, Heavy Duty |

| SPRING WASHERS Single Coil Rectangular, Single Coil Rectangular with Bent Ends, Single Coil Square, Double Coil Rectangular, Crinkle, Curved, Curved Lock, Wavy, Wavy Lock, Conical, Disc |

| TOOTH & SERRATED WASHERS External Toothed, Internal Toothed, External Serrated, Internal Serrated, For Countersunk Screws |

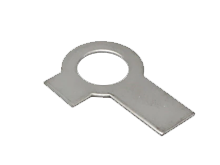

| TAB WASHERS External and Internal, Long and short, Single long Tab |

| TAPERED WASHERS D, Square, U and I Shape |

| CONSTRUCTION WASHERS |

To explore our Bonded Washers selection, click here.

For comprehensive details on our Copper Washers assortment, click here.

What are Sealing Washers (Shim Washers or Rubber Penny Washers)?

Situated underneath a nut, a joint or an axle bearing the purpose of a Sealing Washer is to soften rubbing, spread pressure, keep components apart, and prevent leakage or stop unfastening. To stop vibration from spreading or to ensure that a seal is stable a rubber compound may be the best solution for the application.

Sealing Washers are ideal for surfaces coated with paint, plating or enamel and suitable for use with water, mineral base oils and alkalis, or over a temperature range of -10°C to +80°C. Washers for screwed assemblies offer up to 200 lbf/in2 working pressure.

Sealing Washers are extensively used in Automotive & Motor, Water & Pump, Engineering, MRO, and Manufacturing Industries and are particularly useful on sumps, gearboxes, axles and drain plugs.

Examples of the production process:

- Heat Treatments: Hardening and tempering for alloy steels, annealing for copper, brass, aluminium, and brazing.

- Machine Processes: Blanking, bending, stamping, deep drawing, tapping.

- Finishes: Tumble finishing, deburring, polishing, assembly, packaging.

Some speciality Sealing Washers are certified by FDA, EC1935/2004 & EC2023/2006, WRC, WRAS, USP Class VI, 3-A 18-03 Sanitary Standards and KTW.

If you would like more information about our range, download our Sealing Washers catalogue, visit the Seal Maker Page or contact a member of our team.

E & OE.