Metal O Rings

Metal O Ring Seals for the most extreme applications

M Barnwell Services are the UK’s leading independent manufacturer, stockist, and distributor of Metal O Rings. Metal O Rings are a high-performance sealing solution and are designed to enhance the performance of extreme applications.

Metal O Rings are used when rubber and alternative non-metallic seals do not provide adequate dependability for the installation, most of the time due to stresses, environment or temperatures. Furthermore, they can withstand a broad range of temperatures, hard vacuum, high stresses, corrosive chemicals and intense amount of radiation. Consequently, they are lifelong seals and are not liable to misperformance due to unconformity with the outgassing, environment or from collapse due to age (unlike elastomeric seals).

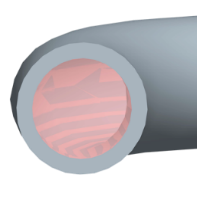

Metal O Rings are typically created from tubing, which usually contains high-temperature alloys (Inconel) or stainless steel. They are frequently used due to resilient features of these materials which make it possible for the seal to ‘spring back’. These materials help to improve adhesion and create a softer surface for the O Ring. By having a softer surface, it allows for the O ring to conform to the microscopic imperfections in the groove or flange. When they are compressed, the Inconel or steel will fill in those irregularities, helping to reduce leakage rates and improving the quality of the seal.

Coating Materials

| COPPER | Copper is a soft material that enhances sealing performance while reducing leakage rates. It is the ideal material for steel rings that require lubrication as it provides good corrosion and tribo-oxidation resistance. |

| SILVER | It is a cost-effective material that is suitable for high-temperature applications. It adheres well and offers superior oxidation and chemical resistance. Silver also improves operational safety. |

| TIN | It improves leakage rates and smooths the surface of the metal seals. Tin offers moderate corrosion resistance and good gas barrier protection but is limited in high-temperature applications. |

| PTFE | This polymer layer provides excellent sliding properties, low friction and high elasticity. It has superior corrosion resistance and is the ideal material to be used in aggressive environments. |

| GOLD | It has exceptional corrosion resistance, wear resistance and workability. Gold is suitable for high temperature and dynamic operations. |

| NICKEL | Nickel provides high hardness, wear resistance and excellent corrosion resistance. It’s ideal for high-temperature and high-pressure applications which reduces the static friction of the metal seals protecting the base metal from corrosion. |

These seals are ideal as static face type seal; however, they are not recommended to be used as a dynamic seal. Therefore, they work just like a gasket between two flanges, which have a very little or no movement between them. They are produced not only in circular shape but also rectangular and many more diverse shapes and configurations.

The advantages of a Metal O Ring Seals include:

- High-temperature capability

- Ability to withstand low temperatures

- Present vacuum

- Ability to withstand extreme applications (radioactive, corrosive)

- Reusable in many cases

- Present a long-term seal – no material disintegration

- Long storage life

- Self-energizing forces

- Optimized spring back, load and outer sealing layered hardness

- Chemical compatibility

Types of Metal O Rings

Metal O Ring Fitting

| CSR | Nominal cross-section: cross-sectional dimension (without coating) e.g. similar to the cord thickness of elastomer O Rings. |

| CODE | Performance Index: shows characteristics of the ring (e.g. pressing load. springback) |

| D | Groove depth: axial design dimension to which the ring is pressed from the original cross-section CSR. |

| F | Pressing load: the mentioned guide values refer to 1mm seal length. To obtain the total load of the seal for the design of the construction, this value must be multiplied by the circumferential length of the seal. |

| ID | Inner diameter of the groove: reference dimension for external pressure applications. |

| OD | Outside diameter of groove: reference dimension for internal pressure applications. |

| ODR min. | Outside diameter of the ring: The outside diameter of the ring is freely selectable from the mentioned minimum dimension ODR min. and is at the same time the corresponding dimension to the outside or inside diameter of the groove. |

| PT | Coating thickness |

| R | Radius: Design dimension that improve the support of the ring under pressure |

| SB | Springback: maximum possible measure by which the ring can spring back elastically overall. Important value in connection with possible flange gaps. |

| Wmin | Groove width: radial design minimum dimension. The specified minimum dimension Wmin. must mot be undercut. |

| WT | Wall thickness: sheet thickness of the ring. |

| Z | Diametric clearance between ring and groove. |

If you are technical and understand your requirements please use this RFQ Form.

For more information about Barnwell O Rings click here, or to contact us click here.

For more information on our range of products click here.

E & OE. Information was gathered from our manufacturing partners.