Hydrogenated Nitrile O Rings (HNBR)

Hydrogenated Nitrile O Rings (HNBR) Supplier – UK

M Barnwell Services stocks a range of Metric and Imperial Hydrogenated Nitrile O Rings (HNBR). It has been developed as an air-resistant alternative to the standard Nitrile Rubber O Rings (NBR). They also have enhanced resistance to heat, ageing, and ozone making the HNBR O Rings great with mechanical applications.

We have over 50 million O Rings and Back-up Rings in stock serving many industries. They include Water, Petrochemical, Offshore Drilling, Agriculture, Earth Moving & Construction, and Automotive.

About Hydrogenated Nitrile and its Features:

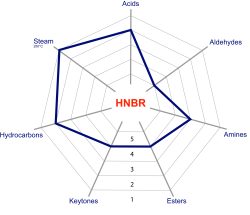

Hydrogenated Nitrile (HNBR) is an outcome of the hydrogenation of Nitrile, affecting fluctuating quantities of saturation of the polymeric sequence. Together with a span of superior physical strength and chemical resistance characteristics, it makes HNBR O Rings ideas for industries that use oil-resistant and high-powered applications.

The temperature range is between -30°C and +170°C (intermittent/compound-specific up to +190°C).

Hardness Range between 30 and 95 (Shore A).

HNBR is also known as Saturated Nitrile (HSN). It is acquired by initiating Hydrogen into the Nitrile in order to saturate the hydrocarbon sequences in the elastomer.

Its physical properties include excellent abrasion resistance, compression set, and impact resistance, good gas permeability, resilience and steam resistance.

Key uses of Hydrogen Nitrile (HNBR) are therefore are oil resistant applications, automotive and oil industries, automotive fuel handling systems and much more.

For further information about our range of materials, visit our Material Properties Page.

If you would like more information about Hydrogenated Nitrile O Rings (HNBR) download our catalogue, see Nitrile Comparison Chart, or contact member of the team.

E & OE.