Ethylene Propylene O Rings (EPDM)

Ethylene Propylene O Rings (EPDM) UK

M Barnwell Services is one of the UK’s leading stockists and distributors of Ethylene Propylene O Rings (EPDM) and other fluid sealing products. With over £50 million O Rings and Back-Up Rings in stock, we serve over 5000 global customers with swift and dependable deliveries.

Our proficient team manages the entire production process, from prototyping and testing to final part manufacturing. Additionally, we offer specialised certification upon request.

If you would like more information about our range, download our catalogue, or contact a team member.

By combining ethylene and propylene monomers, along with the possible addition of a third monomer (diene), manufacturers create a flexible material known as ethylene propylene rubber. This elastomer offers a temperature range of -50°C to +120°/150°C (-60°F to +250°/300°F), depending on the curing system, and certain variations can withstand even higher temperatures.

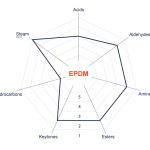

Sealing applications widely prefer EPDM due to its outstanding resistance to heat, water, steam, alkaline substances, mild acids, oxygenated solvents, ozone, aging, and UV sunlight. However, it’s important to note that EPDM compounds are not suitable for use in fuel, petroleum oil and grease, or hydrocarbon environments.

Specific EPDM compounds are also known for their steam resistance:

- EPDM Sulphur Cured – Cost-effective performance up to +120°C (+250°F).

- EPDM Peroxide Cured – Resilience against hot water, steam, alcohols, ketones, engine coolants, organic and inorganic acids, and bases, with a maximum temperature of +150°C (+300°F).

EPDM’s attributes render it well-suited for a variety of industries including Water, Pump, Gas, Automotive, Marine, and Aerospace and Defence.

EPDM O Rings perform well in…

- Alcohols.

- Automotive brake fluid.

- Ketones.

- Dilute acids and alkalis.

- Silicone oils and greases.

- Steam up to 204.4ºC (400ºF).

- Water.

- Phosphate ester-based hydraulic fluids.

- Ozone, aging, and weathering.

EPDM O Rings DO NOT perform well in…

- Aliphatic and aromatic hydrocarbons.

- Di-ester-based lubricants.

- Halogenated solvents.

- Petroleum-based oils and greases.

Applications by Industry

- Automotive: Engine components, cooling systems, fuel systems, and air conditioning systems.

- Water and Wastewater: Pumps, valves, and fittings for water and wastewater treatment equipment.

- Aerospace and Defence: Aircraft engines, hydraulic systems, and various aerospace components.

- Marine: Marine engines, Pumps, valves, and other equipment exposed to saltwater and harsh environmental conditions.

- Food and Beverage: Sealing equipment used in food processing, beverage production, and dairy industries due to their FDA compliance.

- Pharmaceutical: Pharmaceutical manufacturing equipment for sealing various components.

- Chemical Processing: Pumps, valves, and pipes to seal against various chemicals and corrosive substances.

- Oil and Gas: Valves, pumps, and equipment exposed to various chemicals and temperatures in the oil and gas extraction and refining processes.

- Medical and Healthcare: Medical equipment, diagnostic devices, and laboratory instruments.

- HVAC and Refrigeration: Refrigeration systems, air conditioning units, and heat exchangers.

You Are In Safe Hands

As a trusted supplier for leading global OEM manufacturing companies, M Barnwell Services is committed to providing high-quality products and an exceptional level of service that stands out.

With an O Ring inventory exceeding £50 million and supported by five strategically located branches across the UK, we are well-equipped to meet your requirements and exceed your expectations.

EPDM Kits and Selection Boxes are also available with industry-leading lead times. Additionally, we offer a specialised line of EP Pipe Seals that are WRAS approved upon request.

For further details about our offerings, access our catalogue, explore the Material Properties and Material Compatibility Chart Pages or contact a member of the team.