MBE-Barrier Seals

MBE-Barrier Seals: Save Time With This 21st-century Hub Seal

M Barnwell Services provide an extensive range of sealing products for Bus, Truck and Trailer industries, including MBE Barrier Seals. We supply seals for almost all trucks and cars in Europe including shaft seals for engines, powertrain, hub and axle applications.

Manufactured to the Automotive standard ISO-TS16949, MBE Barrier seals are unique and have been developed using the latest technology and materials. The seal addresses two key reasons for premature failure, installation damage and entry of dirt into the seal. The MBE Barrier seal is available in both Standard Material (MBEB) and Premium Material (MBEBP), so that it can replace any existing seal. The seals are fitted in a fraction of the time that traditional seals take to fit, in Truck/Trailer and Bus/Coach applications, saving both time and costs.

Key Benefits:

- Easy to fit – any tool will work, even your hands!

- Impossible to damage during installation

- Standard and premium versions are available

- Unrivalled protection against contaminants

- Eco-friendly, with low friction from the outset

- Match any warrant

MBE-Barrier Seals have three unique features that make them the superior seal

Easy-fit Tough Design

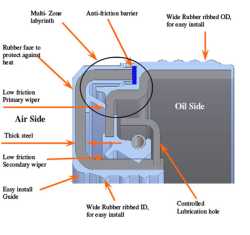

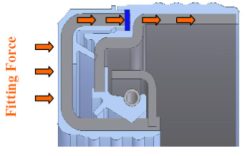

Eradicating the largest reason for premature seal failures – installation damage, was one of the main objectives of the designing process. This was achieved by designing the stiffest profile and using the thickest steel ever used for a seal, right at the front face. The rubber OD beads allow for the minimum fitting force required, and the low friction barrier ensures maximum transmission of the fitting forces to the seals OD.

Low Friction Bumper

The Low Friction bumper performs two major functions, which other seals simply have not got. Firstly, the bumper transmits the fitting force from the front of the seal to the Seal OD in a far more efficient manner than any other seal. Most other seals have a rubber bumper, which acts like a brake, thus increasing the required torque, creating excessive temperatures, and ultimately more fuel to turn the seal. This can last a few hundred hours until the rubber eventually goes hard. Secondly, the bumper acts as the first contacting defence against dirt ingress, as part of the multizone labyrinth protection System.

Multi-zone Labyrinth

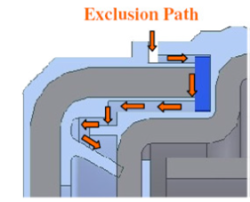

Using the Latest Labyrinth Technology, the MBE Barrier seal provides the best protection and the lowest friction in the market. The combination of low-profile section right angle corners, low friction barrier, two rubber wipers and a specifically formulated waterproof grease, to both lubricate and keep water out, ensures this is the best seal at keeping dirt, grit water and ice out on the market.

Materials

Bus, truck and trailer seals can be broadly categorised by the material used for the sealing lip.

The material properties are key to achieving the maximum life of the seal. With this in mind, thousands of hours have been spent in developing and testing the materials. Two of the main material options are a Nitrile compound (NBR) or a Hydrogenated Nitrile (HNBR). The difference between these two materials, has a dramatic effect on the expected seal life as HNBR has some key benefits over NBR, these being:

- Higher temperature capability, therefore the HNBR lip ages much slower.

- Greater wear resistance, therefore increasing lip life

- Greater compatibility to a wider range of lubricating oils, including synthetics.

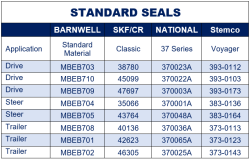

Due to the varying conditions of different applications and to offer the right balance of cost and required performance, the MBE Barrier Seal is offered as two material options, the Standard and the Premium. As shown in the following tables:

We provide onsite consultation, sample identification and technical support for your requirements.

Contact us for more information on our range of Bus, Truck and Trailer Seals or request a quote.