Importance of O Ring Lubrication

Why is O Ring lubrication important?

Why lubricate?

All kinds of lubrication, including oils, greases, water and air are used to reduce wear by minimising heating and friction of moving elements. Any substance that accomplishes this, can be called a lubricant.

Types of lubricants

Lubricants help reduce friction in the application. These lubricants can be:

- Semi-Permanent Lubricant Coatings

There are many applications that require a lubricant, but temporary external lubricant’s greases may contaminate the application. For such applications, Semi-permanent coatings are required. These ensure good lubrication to the elastomer without the risk of contamination. Two common semi-permanent lubricants are PTFE (Teflon) coating and Parylene coating. These coatings can flake and peel over time and so are not absolutely permanent.

- Temporary External Lubricants

The lubricating agent is applied and remains on the surface of the seal. It can be removed by special solvents or fluids. Temporary external lubricants can lower pinching, cutting and abrasion throughout the assembly and installation process. The Temporary external lubricant can function as a barrier between the detrimental system chemicals and the rubber, which in turn increases its service life. It is important to note that compatibility examination must be carried out before the use of a specific lubricant. Several lubricants can swell the elastomer seal material and deteriorate its physical characteristics. A good example of this incompatibility is Silicone Lubricating Oil making a silicone seal swell.

- Internal Lubricants

A lubricating agent is blended into the elastomer before moulding. This lubricant is scattered equally throughout the rubber before vulcanisation. It lessens the ratio of friction of not only the surface but the whole rubber element. PTFE (Teflon) is an example of an internal lubricant that is blended into an elastomer.

What to consider when deciding on the form of lubrication?

Temperature – grease doesn’t operate well at high temperatures due to being unable to dispose of the heat. At low temperatures, grease stiffens and can clog up elements and stop them from moving.

Stability – a job of a lubricant is to preserve its consistency when playing its role of lowering friction and heating between moving elements. If it gets softer or harder when functioning, it is known to be unstable.

Consistency – grease consistency is crucial when choosing the lubricant because getting the lubrication to where it’s needed and having it NOT leak out is critical.

Water resistance – considering the use, the lubricant has to have a steady amount of water resistance, so it can proceed to work normally in case water is in the system.

Pumping ability – the majority of plants that use machinery have some kind of automated grease dispensing system. These systems pump grease via nozzles and lines to the elements that need lubrication. It is a cost-effective method. Several lubricants won’t move through the lines under stress, therefore pump ability of a lubricant is important.

What does a lubricant consist of?

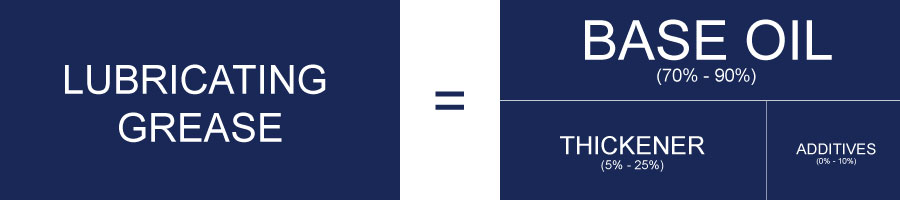

There are several different kinds of lubricant grease for all different purposes and applications. However, all greases share similar anatomy:

BASE OIL (70% – 90%) – Mineral oils: solvent refined, hydrotreated, hydrocracked (purest and most expensive); Synthetic oils: synthesized, silicone, ester, glycol, polyester, bio lubes.

THICKENER (5% – 25%) – Metal Soaps: lithium, sodium, calcium, aluminium; Complex Soaps; Mixed Soaps.

ADDITIVES (0% – 10%) – Improve properties: extreme pressure (graphite, molybdenum), thermal stability, corrosion resistance, antiwear.

Various sizes of Lube are available (MBMS0783, MBMS0260, MBMS0488) – Request a quote today.

M Barnwell Services also offers a full range of Sealants and Adhesives. To view visit the Sealants, Adhesives and Lubricants page or contact a member of the team.

E & OE. M Barnwell Services endeavour to make sure that all content is correct. Information has been gathered from manufacturing partners.