BSP & BSPT: The Differences

What are BSP & BSPT Threads?

Here we will guide you in understanding the what the differences are between BSP Threads and BSPT Threads. BSP (British Standard Pipe) and BSPT (British Standard Pipe Tapered) are types of pipe thread standards used primarily for plumbing and pipe fittings, especially in the UK and countries that follow British Standards (BS).

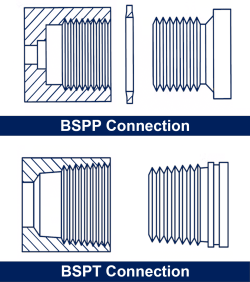

The main difference between BSPP (British Standard Pipe Parallel) and BSPT Threads is the type of thread they have. BSPP threads are straight whilst BSPT are tapered. BSPP are designed to be used with sealing mechanisms such as O-Rings or Gaskets. This is ideal for fittings with the same sized pipe section without the need for tapering. BSPT are designed to create a seal as they tighen due to their taper. This shape allows a mechanical seal to be created when the male and female parts are screwed together, without the need for extra sealing components.

Applications:

BSP: Commonly used in applications that require a parallel thread, particularly involving hydraulic fittings and some plumbing connections

BSPT: Used in high-pressure systems and certain industrial applications

Identification:

BSP: BSP threads are identified by the same diameter throughout their length

BSPT: A gradually increasing or decreasing diameter along their length (55° angle for flank of the thread)

Standards for BSPT threads:

EN 10226-1, ISO 7.1, BS 21, DIN 2999, and JIS B0203.

At M Barnwell Services Ltd, we are proud to be the UK’s trusted supplier of high-quality fluid sealing solutions. Our extensive range of products is designed for water and gas applications and meets both European and global standards, including WRAS-approved seals.

We’re known for delivering exceptional products, backed by outstanding service and technical expertise. Our materials comply with industry standards such as WRC / WRAS (BS6920), NSF, DGS / ACS, EN681-1, EN682, KTW / DVGW / W534 / W270, and KIWA, ensuring suitability for a wide range of applications.

Our stock includes the BS1806 Imperial Range of ‘O’ Rings, covering sizes BS005 to BS245. Manufactured from Black Nitrile 70 Shore (NBR), our MBMS0003 compound meets water certification standards (WRc, KTW, ACS, and NSF61) and gas accreditation (EN549). These seals are ideal for hot and cold water systems.

We can also provide onsite consultation, sample identification and technical support for your requirements.

Contact us for more information on our range of WRAS Approved Seals or request a quote.

E & OE. Data provided by manufacturing supply partners.