What is an O Ring

What is an O Ring – Selecting, Material and Storage

In this news/blog item, we look to answer what is an O Ring?

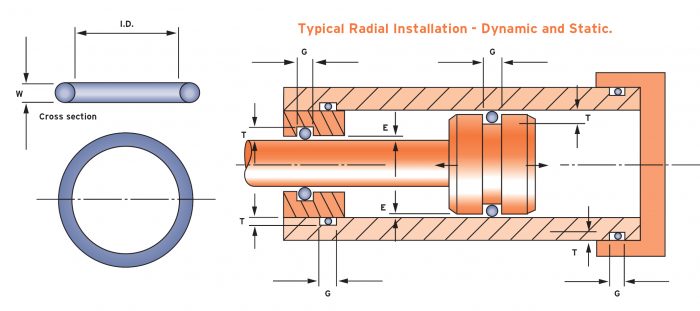

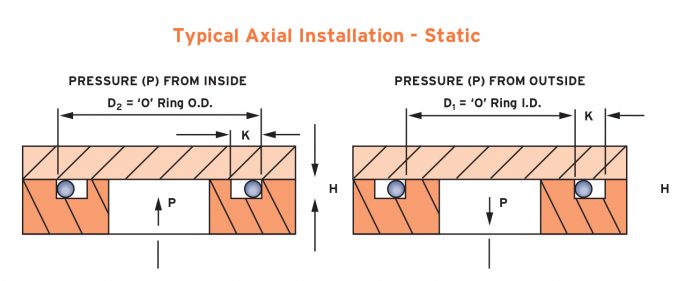

The O Ring or Toroidal Seal is a simple, versatile and economical device with a vast range of uses. The most common of these is a static seal replacing a gasket or sealing washer, but it can also be utilized as a single or double acting dynamic seal. It can be used to seal radially in both internal and external positions as well as axially on its faces.

Its circular form with an annular cross-section in a variety of synthetic elastomers offers inexpensive production methods for both low and very high volumes, depending on size. In short, the O Ring has become irreplaceable for sealing a multitude of both simple and complex applications dealing with both liquid and gaseous media. This news item is intended, to be a GUIDE TO O RING SELECTION from the ever-increasing range of sizes and materials now available to the user.

What is an O Ring: Selecting an O Ring

1) If replacing a worn or damaged seal, first measure the cross-section “W”. This should quickly establish whether it is an imperial (inch) size (BSI806), a metric standard (BS4518) or another metric size. Once this is established, look through the appropriate section of the O Ring brochure (see index). Then check the inside diameter (I.D.). as accurately as possible, preferably with a vernier caliper. Generally, O Rings are described by I.D. X section (e.g. 10 x 2,5) so with these two measurements, you are able to choose the closest available O Ring – FROM STOCK. If in doubt select a slightly larger section – as it will almost certainly be compressed with a slightly smaller I.D., as often this can be stretched. Of course, the “exact” size is always best.

2) If for some reason the O Ring is missing and all you have is the shaft, rod, piston or housing, often referred to as ‘the metalwork’, then you can use the application descriptions on page 5 of the O Ring Catalogue and the groove dimensions on pages 30 and 31 to decide what is the closest size O Ring, again bearing in mind the points made in section 1.

3) If you are at the design stage there are a multitude of considerations, but try to keep your selection simple. As far as possible choose ex-stock sizes and material. Only specify exotic or completely non-standards if you have no other choice. Keep to the recommended surface finishes and tolerances. You will need to know the application and media; static or dynamic, as this can influence the size and material you choose; the temperature the O Ring has to withstand can affect the material you should use; the pressure it has to cope with will affect the rubber hardness requirements, as well as the size of groove and the extrusion gap. If the pressure is high the gap must be kept to a minimum and anti-extrusion or back-up washers must be incorporated in the design – resulting in wider grooves.

If these factors are not known, you will have to make a more general assessment. So select the largest section O Ring to fit the nominal groove diameter. This will tolerate the widest range of metalwork size differences, surface defects, and high temperature.

Consider how the O Ring is to be fitted – a 5% stretch is acceptable but only a 3% outside diameter compression is advisable. The cross-section has to be squeezed in order for it to function, but do not make this too great, particularly with dynamic applications. Keep to the size deformation suggested in the groove depth section. Take note of sizes marked* when a dynamic application is being sealed. Provide for good leads and chamfers, remove all sharp edges and recommend the use of fitting tools and suitable lubricant during fitting operations.

The exception to the above is on the very rare occasion when gas permeation may be a consideration. Then, keep the smallest cross-section that will effect a seal in a groove size of almost equal volume. It is important to seek advice at this stage as Explosive Decompression requires special materials and size selection.

What is an O Ring: Material Selection

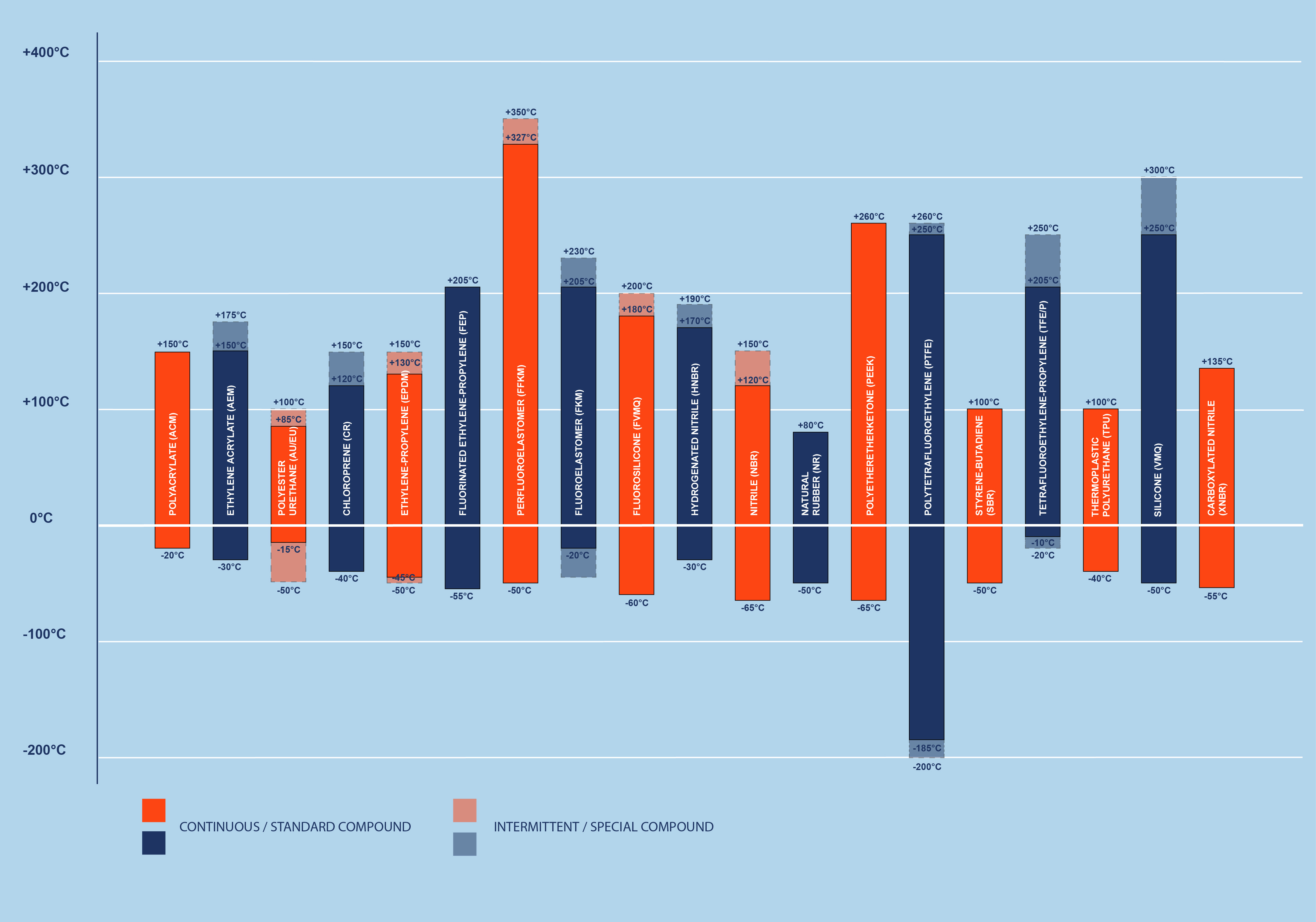

The most commonly used O Ring material is Nitrile 70° Shore ‘A’ (NBR 70). This elastomer can seal the majority of “normal” industrial applications including water, oil, petrol and most mild chemicals up to 100°C and 1500psi, providing the mating surfaces and housings are adequate.

Consideration must be given for low temperatures (below -30°C), high temperatures and pressures, as well as hazardous chemicals and solvents. There is also an increasing demand for specific materials approved for use with Food Machinery (FDA), Potable Water (WRC) and the various Gas Standards. A commonly overlooked sealing requirement is for ozone, weathering, ambient etc., where Neoprene (CR), EPDM or Silicone (VMQ) perform better than Nitrile (NBR) in most circumstances.

For technical support see pages Materials Property, Approved Materials, Material Compatibility Chart or contact a member of the team today.

Temperature range of popular materials:

What is an O Ring: Storage

BS 3574 (1989) is a good guide for synthetic rubber shelf life. O Rings should be stored in an unstressed condition, away from extremes of temperature, ozone, and sunlight. Sealed opaque dust proof plastic bags are best. Avoid staples, wires, and nails – they cause untold damage resulting in leakage.

If you would like more information about our range of O Rings, download our catalogue, visit the O Ring Page or contact a member of the team.